In this interview, Massimo Palomba, Global Sales Manager for E-Mobility at Bonfiglioli, shares insights into the company’s latest developments and market challenges.

Bonfiglioli, a global player in power transmission and drive systems, positions itself in the heavy equipment industry through strategic innovation and integrated solutions. Headquartered in Italy, the company is renowned for its gear motors, planetary gearboxes and fully integrated drive systems that serve a wide range of sectors, including construction, mining, material handling, and renewable energy.

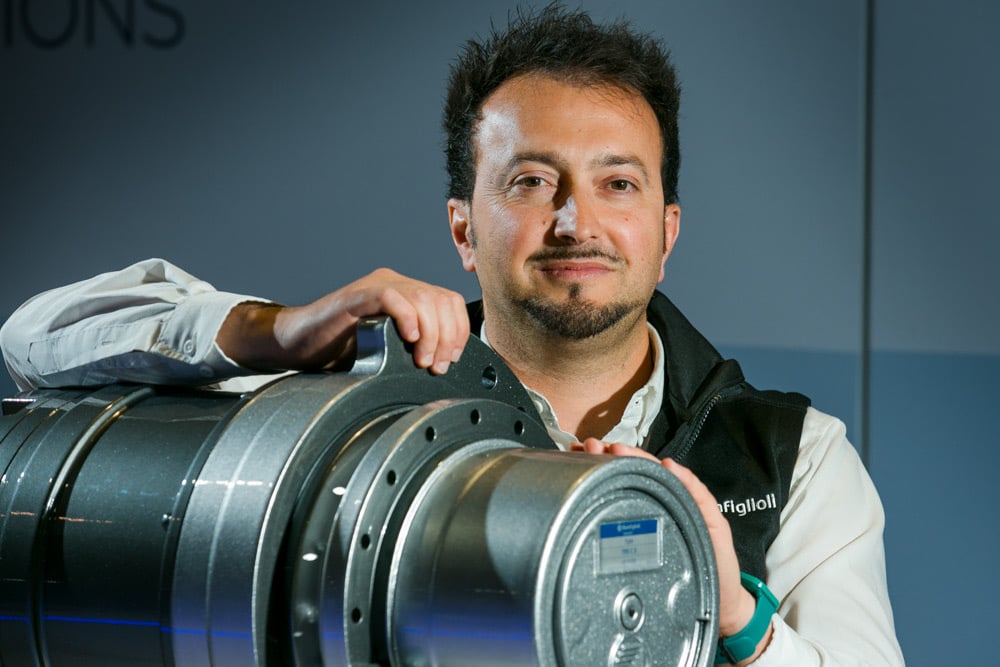

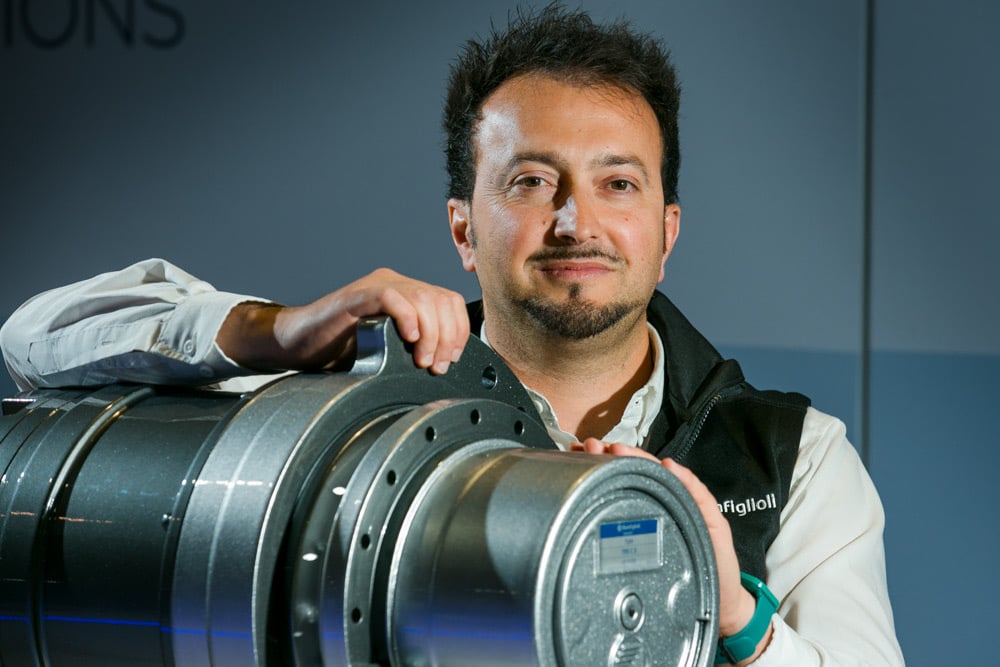

Massimo Palomba, Global Sales Manager for E-Mobility at Bonfiglioli.In the construction and heavy equipment segment, Bonfiglioli offers a portfolio of applications tailored for both hydraulic and electric-powered machines. Key offerings include travel drives and slew drives, such as the 700CP and 700T Series – compact and robust units ideal for mini-excavators and mid-sized construction machinery. Furthermore, with the 600WE Series, Bonfiglioli delivers complete electric drive solutions that integrate high-performance permanent magnet motors with planetary gearboxes, meeting the rising demand for electrification in compact machines.

At the forefront of this transformation is Massimo Palomba, Global Sales Manager for E-Mobility at Bonfiglioli. In this interview, Palomba outlines the company’s latest developments in electrification, system integration and digital services, highlighting how Bonfiglioli is shifting from a component supplier to a comprehensive solutions provider in a rapidly evolving market.

Q: This year, Bonfiglioli has introduced new developments in both hydraulic and electric systems. Could you elaborate on these innovations?

A: The 700CP series – hydraulic track drives for mini-excavators – is now fully engineered and manufactured in-house by Bonfiglioli, marking a strategic shift from partial production by Poclain to 100% internal production by Bonfiglioli. By integrating this production in-house, we gain greater control over the entire transmission system, which is particularly beneficial for mini-excavators and small construction machinery. This move not only enhances system integration but also offers cost advantages for our clients.

Q: Does this internalisation mean you now have full control over the production process?

A: Exactly. Bringing the product line 100% internally makes us responsible for its design, allowing us to optimize the entire system. We’re working on refining the original design and plan to introduce some innovations at upcoming trade shows.

Q: Regarding OEMs, are your products customized per client requirements, or are they standard designs that clients must adapt to?

A: Customization is always present in our sector. We strive to balance tailored solutions with lean production practices. Internally, we aim to use standardized components, but we customize the external interfaces to meet specific client needs, making each product unique.

Q: Would you say that flexibility is one of Bonfiglioli’s strengths?

A: Absolutely. Our business model is based on co-engineering, forming partnerships with clients. We often engage in a co-engineering phase lasting up to two or three years to define product characteristics. This is followed by prototyping and field validation, leading to a series supply that typically spans 7 to 10 years, with minor improvements along the way.

Q: How is Bonfiglioli leveraging its experience in electric systems for compact machine electrification?

A: Our longstanding experience in producing and designing electric motors, especially for wind energy and industrial applications like beverage and packaging industries, gives us a competitive edge. This foundation allows us to integrate entire systems more effectively compared to competitors who have had to acquire this technology.

Q: Are you also developing Saas solutions as part of your electric system offerings?

A: Yes, our engineering team is collaborating with partners to provide comprehensive solutions. Our goal is to transition from being a component supplier to a solution provider, offering clients complete answers to their machine movement needs.

Q: How are you preparing to offer machine monitoring services?

A: IIOT is a key part of our strategy. We’ve established a dedicated unit within our engineering department that focuses on software, specifically the models which are used to give meaning to the data acquired either from the sensors or from the inverters, the latter control our electric motors within our electrified solutions.

Additionally, Bonfiglioli has developed its own proprietary sensors, which are integrated directly into our products. These sensors transmit data to a cloud-based platform, also developed in-house. The platform is designed to process, filter, and analyze large volumes of operational data in real-time.

From this data, we’re able to extract valuable insights across two main areas:

- Predictive Maintenance – This is particularly important for large-scale machinery, such as equipment used in mining operations. These machines are incredibly expensive and must operate continuously. Downtime -sometimes costing hundreds of thousands of dollars per hour – must be avoided at all costs. Our sensor data allows us to detect anomalies early and anticipate failures before they occur, helping operators avoid critical breakdowns.

- Usage Analytics – For compact equipment, especially when part of a fleet, we provide tools to analyze how the machines are being used. Fleet managers can identify patterns of operator misuse or inappropriate handling that could lead to premature wear or damage. This allows for proactive intervention and training, ultimately increasing uptime and machine lifespan.

Q: Is your cloud solution integrated with OEM platforms, is it a white label service, or is it a proprietary system offered to end-users? What model are you offering?

A: Our model is quite flexible. In some cases, we simply sensorize the mechanical and electrical components, and the data is then transmitted to the client’s own cloud infrastructure, which handles both acquisition and analysis.

Alternatively, we can provide a complete solution, including the analytics platform. We use a standard serial data interface that can either connect directly to the customer’s system or operate within our own end-to-end environment.

The real value-added aspect of Bonfiglioli’s offering lies in our deep product knowledge. Only the original manufacturer of the transmission truly understands its internal structure and behaviour. So, when we receive sensor data – such as vibration levels or temperature increases – it is only through this intimate understanding that we can correctly interpret what’s happening inside the unit.

In essence, while raw data can be made available to anyone, what makes the difference is how you read it. That’s where our engineering expertise comes in. The analytical models we’ve developed are based on decades of experience with how our transmissions are designed and perform in the field. This is what allows us to deliver real predictive insights, not just data.

Q: Given the current competitive market and the entry of Chinese competitors, what challenges does Bonfiglioli face?

A: The market has indeed become more competitive, especially with recent tariff announcements. We’ve observed significant changes, particularly in China, where local component manufacturers now dominate. Consequently the Chinese market has become less accessible to us, there we’ll be likely forced to focus on niche markets that remain profitable and viable for Western manufacturers. Hence, it requires a dedicated strategy compared to the European and American markets. Given the importance of the Chinese market, we are anyway ready to take the challenge.