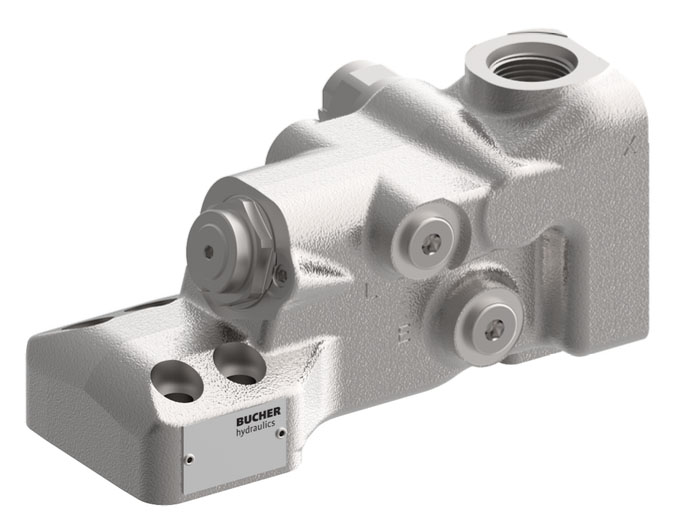

Bucher Hydraulics introduces the newly designed excavator pipe-rupture valve CFS-flat to the market. It is an innovative product range extension of the CFS-building block. Well-placed, tried and tested – the CFS technology is thus available in a flat design.

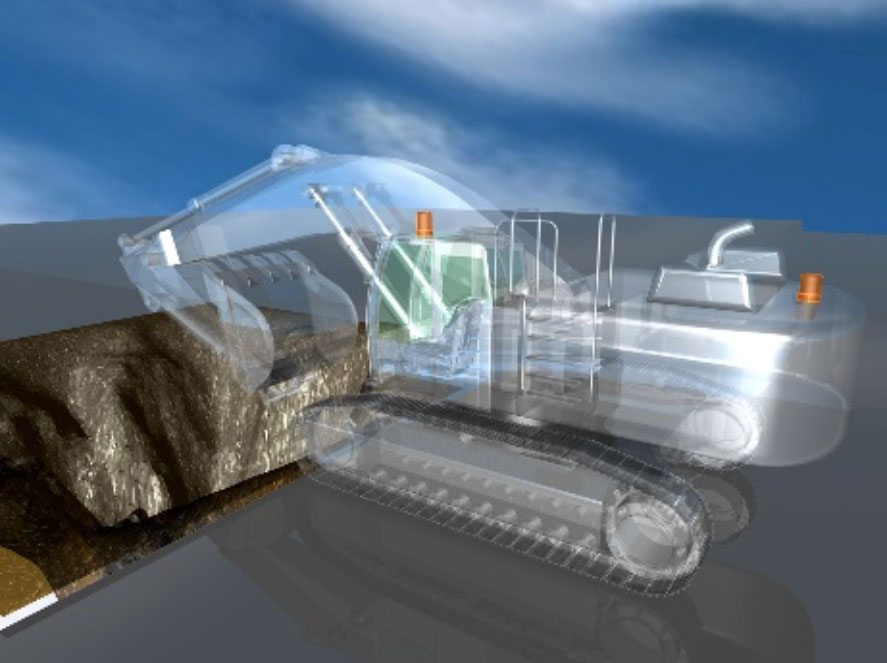

The excavator pipe-rupture valve is used wherever so required by the standards ISO 8643, EN 474 and DIN 24093 for excavators with a lifting device (e.g. a load hook on the bucket). The actuators concerned are the lift cylinders, the stick cylinders and the adjusting cylinders. The valve should also be used on machines in which a pipe-rupture on the actuators could produce a dangerous situation (e.g. machines for materials handling and demolition).

Bucher Hydraulics developed the excavator pipe-rupture valve, series CFS (Compact Flow Control and Safety Valve), to prevent uncontrolled lowering of the actuator in the event of a pipe- or hose-rupture.

In addition, the CFS valve holds the actuator in its position when the main valve is centered. The valve also includes a secondary pressure-relief function, which protects the actuator against overload. The inlet and actuator ports on the CFS are standard SAE flanged ports, and the valve can therefore be retrofitted to existing equipment without any difficulty.

Thanks to its almost load-independent, pilot operated principle, variations in load pressure – even right up to the maximum – have no effect on the fine-metering characteristics and the hydraulic performance of the valve. The innovative design of the valve permits that very small lowering pressures can operate it. The valve adjustment is integrated into the hydraulic circuit in a way that ensures that the excavator pipe-rupture function has no effect on the hydraulic values that have already been set in the machine.

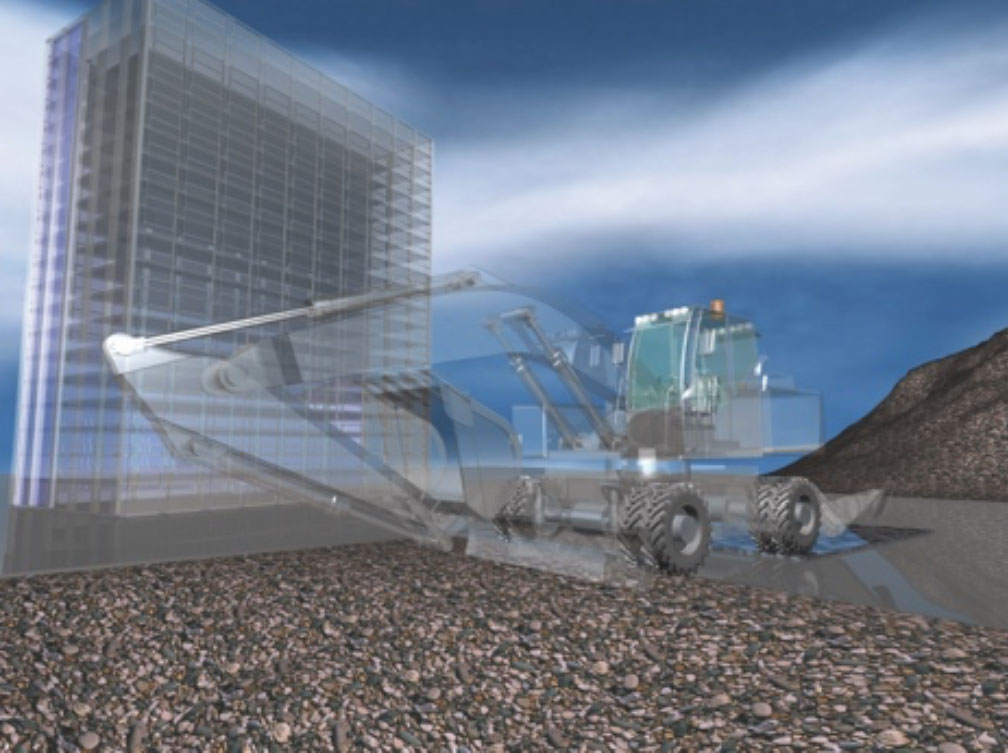

Typical applications for this high-quality valve are crawler- and wheel excavators.

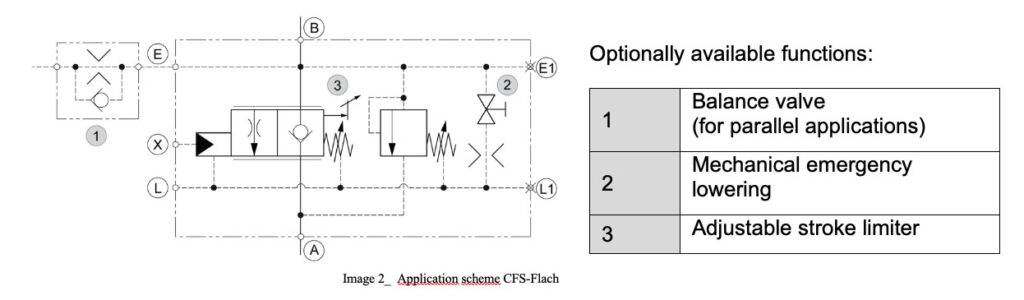

Symbol and options

Technical data

| Design | Pilot-operated seat valve, flat design |

| Maximum flow rate | 350 l/min |

| Maximum operating pressure | 420 bar |

| Actuation type | Hydraulic-proportional |

| Opening pilot ratio | 480:1 |

| Opening pressure range | 4.4 … 16 bar |

| Surface protection | all external parts with zinc-nickel coating according to DIN EN ISO 19598 |

Functions

Rest position / neutral position:

In the neutral position, the excavator pipe-rupture valve is held closed by the spring, which acts on the control spool and by the load pressure acting on the back of the control spool.

Lifting: (Volume flow direction A → B)

To raise the actuator, pump pressure is applied via port A to the valve-seat area of the control-spool and causes the control spool to open, pushing against the light pressure spring.

Lowering: (Volume flow direction B → A)

1. Decompression

The pilot pressure at port X moves the pilot piston in opposition to the pressure springs and opens the pilot spool at the set pressure. The load pressure behind the control spool now decays as it escapes past the pilot spool to port A. The progressive characteristics of the decompression phase ensures that the actuator motion begins smoothly and without jerks.

- Main opening

With further increase in the pilot pressure at X, the pilot spool opens further and the reduced pressure behind the control spool falls still more. The load pressure acting on the differential area of the control spool now pushes the spool off its valve seat in the opening direction until the pressures of the oil flows into, and out of, the control spool has changed enough to produce a situation of force balance.

The pilot pressure acting on the pilot piston therefore controls the open metering area of the control spool, and consequently the flow rate from B → A. The pilot valve is compensated and operates independently of any backpressure in port A.

The opening point of the pipe-rupture valve is precisely matched to the particular make/model of excavator and is set to the required value on the test bench using an adjusting screw. With optional stroke limiter, the pilot spool can be restricted additionally and thus influence the lowering speed.

Features

- Fulfils safety requirements in accordance with ISO 8643, EN 474 and DIN 24093

- High opening pilot ratio (480:1)

- The control assembly is guaranteed to close → it closes even with a broken spring

- Satisfies exacting demands on corrosion protection → valve zinc plated (Cr VI-free)

Advantages

- No impact, or only very low impact on the existing hydraulic system → easy to retrofit

- Constant calibration due to low hysteresis

- Valve is independent of backpressure

- No dynamic seals in the main spool and in the pressure-relief valve

Benefit (OEM)

- Excavator pipe-rupture valve perfectly tailored to the main spool valve and easy to retrofit

- Consistent valve function, e.g. reliable fulfilment of the ISO 8643-Norm

- Minimal installation time thanks to symmetrical assembly of the valve

- Long service life and usable under varying operating conditions

Benefit (End User)

- Load-independent travel behavior for the equipment operator

- Increased safety for people and equipment even in the event of malfunction

- Cost savings thanks to better energy efficiency

- Optimal operation as the excavator pipe-rupture valve is tailored to the main spool valve

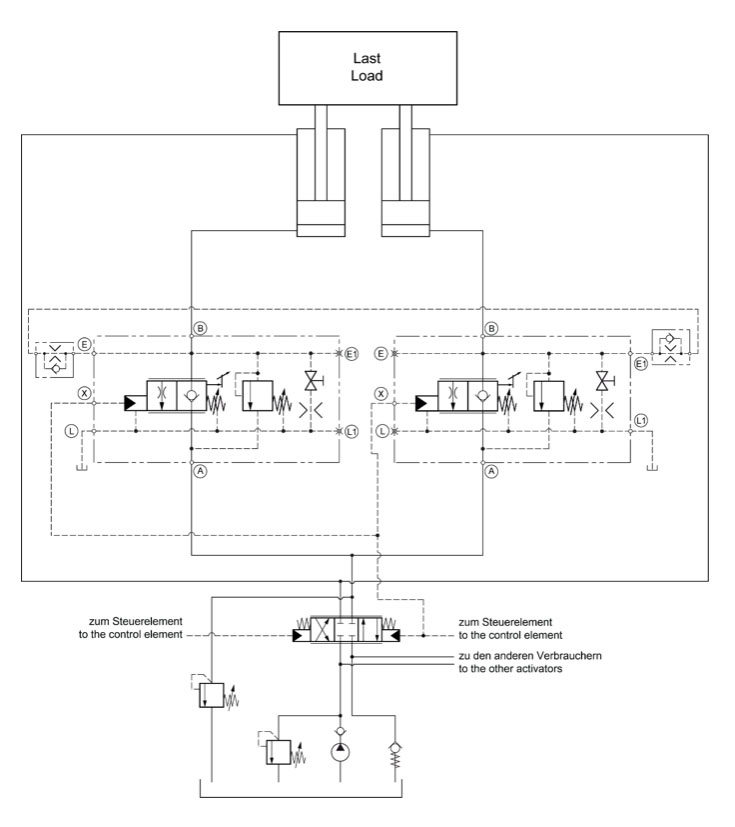

Application examples

Parallel application

Source: Bucher Hydraulics

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.