The 3-cylinder, 3.3-litre AGCO Power engine meets emissions stage V with a diesel oxidation catalyst (DOC), diesel particulate filter (DPF) and selective catalytic reduction (SCR) but without exhaust gas recirculation. There are also maintenance-free hydraulic tappets built into the engine. The electronically controlled Visctronic fan runs just when it is needed. It works quieter and saves fuel.

The Fendt 200 VFP Vario’s new 4-pillar cab is more spacious than its predecessor and offers more headroom.

The new cab means the cab air filter system can be converted to protection category 4 ex works. In its basic configuration, it meets all the standards of a cab with protection category 2. The filter system can also be upgraded to protection category 4 in accordance with EU standard EN15695, with protection against dust, liquid fertilisers and their vapours.

The Fendt 200 VFP Vario meets all requirements for plant protection use and keeps the driver safe.

Once the work is complete, the filter system can be easily converted via the terminal. There is a new control console with multifunction joystick for easy and intuitive machine operation.

An optional front power lift relief-control system is available for the Fendt 200 P Vario. The field pressure is easy to finely adjust on the terminal – for better traction and excellent ground tracking. It promises improved climbing power and fantastic results even when switching from slopes to flat ground. The Fendt 200 VFP Vario also offers fully equipped implement attachments at the front, rear and on both sides for intermediate axle implements.

Long working days in the extreme wintry weather conditions can take their toll on the driver. Now they can work in complete comfort with their new cleverly designed footwell heating system, for improved working comfort during the winter months.

The Fendt 200 VFP Vario Profi comes with the 10″ digital dashboard as standard. You can also opt for the 12″ terminal in the roof liner above the windscreen, to give the driver more display area. The terminal display can be configured to suit the driver.

With the standard load-sensing pump (LS) and optional 3L joystick, the Fendt 200 Vario Profi is equipped for using complex equipment. The 3L joystick can be used, among other things, to operate a leaf remover with an integrated function for the 3rd hydraulic circuit. Power Beyond connectors or two additional central hydraulic control units extend the hydraulic equipment from the Profi variant upwards. This gives you up to 8 proportional control units, including the front power lifts.

With Fendt Task Manager, the farm manager can create job orders in the office or on the move and send them straight to the machine. Use Fendt Task Manager together with Fendt Guide and the RTK correction signal, and the Fendt 200 VFP Vario can drive down rows with centimetre-accuracy and process the fields more efficiently.

When spraying, you can avoid going over the same spot twice with your pesticides. Once the work is done, Fendt Task Doc can automatically send the job order to the office. This makes it easier to document the work carried out.

The 12″ terminal can show various machine functions, lane guidance options, ISOBUS functions and attachment functions, and the display can be customised to suit the driver’s needs. In special crops like wine, fruit or hop cultivation, a tracking system on the tractor or attachment makes the work much easier, especially when first planting. You can use it for arranging piles and plants with centimetre-accuracy and getting the follow-up work done more easily and efficiently.

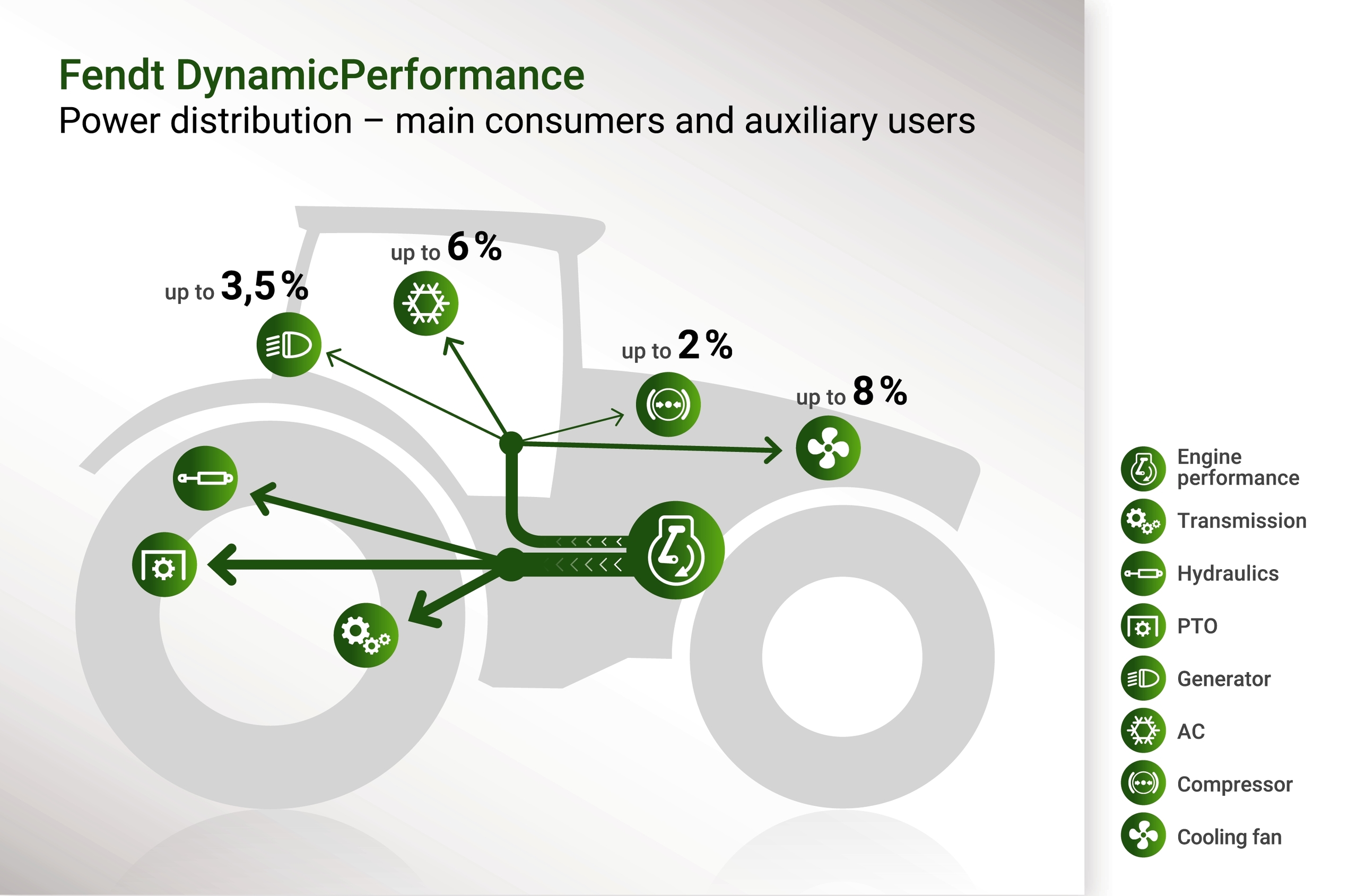

The innovative power-boost concept DynamicPerformance (DP) on the Fendt 211 VFP Vario releases 10 hp more power on demand, just when it’s needed. It is not tied to driving speeds or special operational tasks, but works purely dynamically.

Typically, the engine power of tractors is distributed across numerous power consumers – such as the PTO, hydraulics, engine fans and air conditioning. The system detects when certain components need more power and then provides a boost with smart control.

The DP power boost concept comes into action at a standstill, but also during transport and field work. Fendt DynamicPerformance comes into use on the Fendt 200 VFP Vario when towing a crop harvester or using the sprayer on a steep slope, depending on the power consumers at the time. The 10 hp extra boost of power from the Fendt 211 VFP Vario is good for companies that need a powerful narrow gauge tractor with additional power reserves.

The Fendt 200 Vario will be available for purchase from July 2020, rolling off the production line from January 2021.

Source: AGCO

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.