SAF-Holland and British motor manufacturer AEM (Advanced Electric Machines) are working together on the suspension specialist’s electric axle system: AEM is supplying an innovative electric motor for the SAF Trakr regenerative braking axle that does not require any rare earth or copper.

Rare earths are valuable raw materials that are only used in very small quantities, for example in notebooks, smartphones, or even electric motors. The extraction of these special metals places a huge burden on the environment: Each tonne of extracted rare earth material produces high amounts of toxic and corrosive waste gases such as sulphur dioxide as well as acidic waste water. Thanks to a patented technology, AEM’s HDSRM150 machine is completely free of rare earth elements, such as the chemical elements neodymium and dysprosium. Moreover, AEM is aiming to replace the copper windings with aluminium to improve recyclability. Furthermore, the absence of copper makes the motor lighter without reducing overall efficiency.

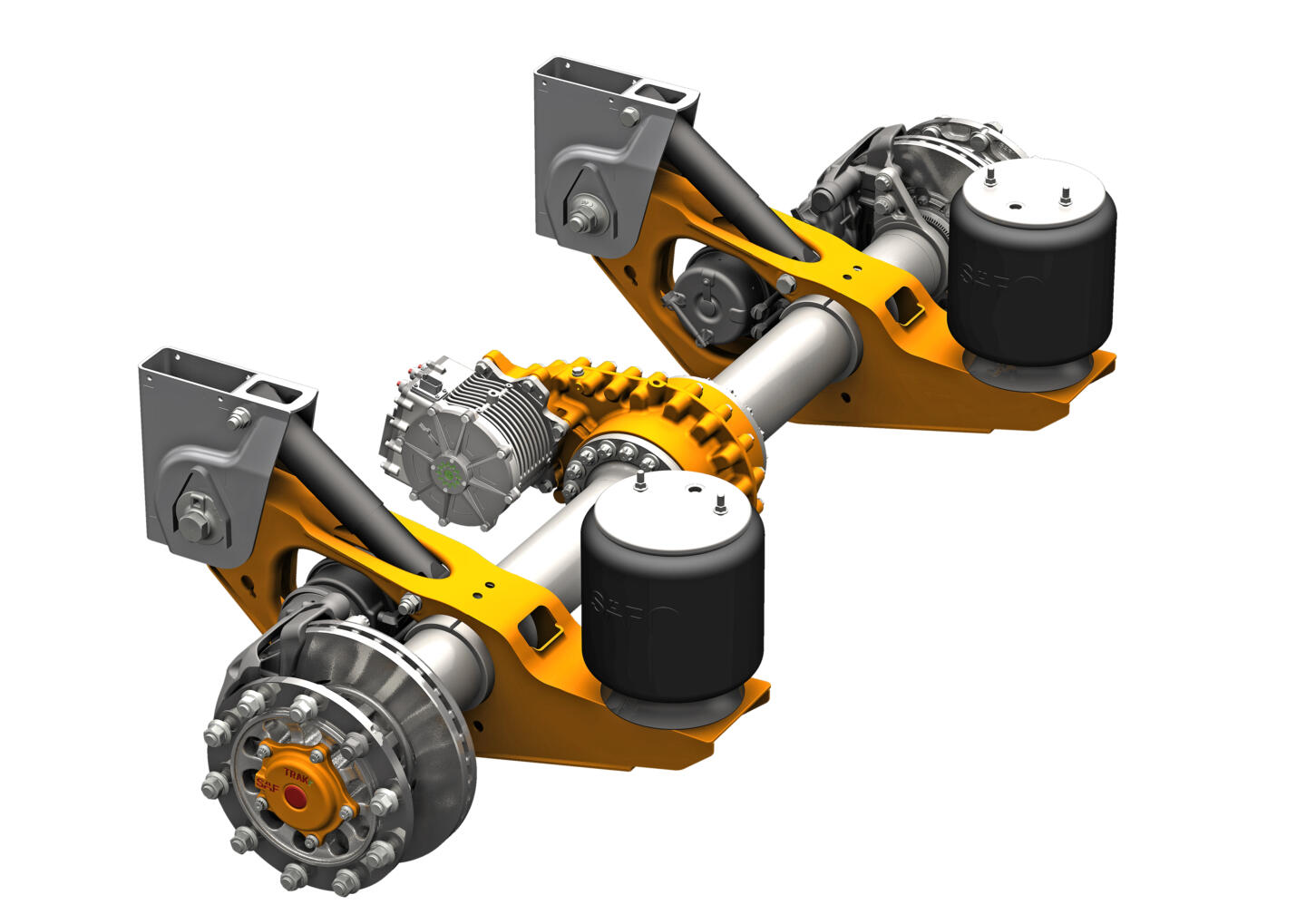

Sustainable combination: Axle and generator

This sustainably produced electric motor is installed in the new SAF Trakr electric axle. It uses recuperation, which converts the vehicle’s kinetic energy into electrical energy. This is temporarily stored in a lithium-ion battery and then used for auxiliary units in the trailer, such as pumps or cooling systems. Recuperation as an additional source of power generation saves fuel, while reducing noise and exhaust emissions from the vehicle.

“Every litre of diesel saved counts – which is why we developed the SAF Trakr to electrify commercial vehicle trailers and reduce the load on the tractor unit. AEM’s HDSMR150 machine is perfect for the job as it is powerful, efficient, yet also as sustainable as possible,” said Olaf Drewes, Director Group Innovation EMEA at SAF-Holland.

For James Widmer, CEO of AEM, the collaboration is a significant step forward:

“SAF-Holland is undeniably one of the leading commercial vehicle suppliers in the world, and we are delighted to be working with them. The signed Memorandum of Understanding is an important milestone for AEM as we look to further expand our business in order to make the world’s most sustainable electric motors available to Tier 1 and trailer manufacturers.”

More about AEM

Founded in 2017,AEM has established a multi-disciplinary team, with world class expertise in design and manufacture, led by CEO James Widmer and CTO Andy Steven. AEM’s vision is to design and build the world’s most sustainable electric motors for the global automotive and transport industries. To ensure sustainable, efficient and cost-effective solutions, the company utilises its expertise in materials, manufacturing and design to deliver no compromise solutions which deliver market leading performance, efficiency and cost. AEM has registered several international patents on its technology and is working with customers across the globe in the commercial vehicle, passenger car and aerospace sectors.

More about Saf-Holland

SAF-HOLLAND is one of the leading manufacturers of chassis-related systems and components, primarily for trailers, but also for trucks and buses. In addition to axle and suspension systems, the product range also includes fifth wheels, kingpins and landing gear and is marketed under the SAF, Holland, Neway, KLL, V.ORLANDI and York brands. SAF-HOLLAND supplies original equipment trailer manufacturers (OEM) on six continents and works closely with fleet operators and freight forwarders. The latest development is the SAF TRAK family, which includes a hydraulically driven axle as well as the SAF TRAKe and SAF TRAKr electric axles.

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.