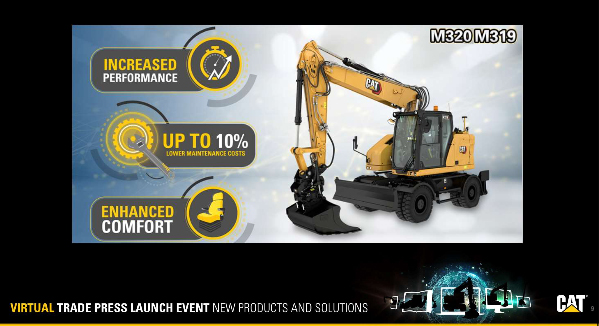

Our team was glad to take part to Cat Event where it was presented the new Cat M319 wheeled excavators and Track Loaders were presented.

***

Making no compromise on performance, the new Cat M319 wheeled excavator features a short front-end design and tail swing to efficiently work in confined areas. Delivering up to 15% more swing torque than previous models, this Next Gen excavator quickly gets the job done. A dedicated swing pump improves operating efficiency by providing more consistent power for better multitasking capabilities.

Powered by the 128-kW (171-hp) Cat C4.4 engine, the M319 tailors performance and production to jobsite needs while meeting EU Stage V and U.S. EPA Tier 4 Final emissions standards. With features like Eco mode to minimize fuel consumption in less demanding applications, the excavator uses up to 5% less fuel than previous models, lowering long-term owning and operating costs.

High performance, limited swing

The new M319 spends more time working by quickly traveling between sites at speeds reaching 35 km/h (21.7 mph). With its minimal 1900-mm (6-ft, 3in) tail swing radius, operators can complete dig, swing and dump tasks with limited side overhang when working on tight jobsites.

Its updated advanced hydraulic system delivers the optimum balance of power and efficiency, while offering the control required for working precision. To increase machine flexibility, auxiliary hydraulic options of high- and medium-pressure circuits with one/two-way pressure flow allow contractors to tailor machine configuration for using a wide range of Cat attachments.

Whether working from dirt or asphalt, the M319 tackles a range of projects from utility work to general excavating to trenching. A standard high-ambient temperature capability of 50˚ C (125˚ F) and cold-start capability of -18˚ C (0˚ F), plus working at altitudes as high as 3000 m (9,843 ft) without derating, the excavator meets contractors’ needs for productively completing projects in a range of operating environments.

Premium comfort

Boosting efficiency and comfort, its reengineered cab delivers a premium operator experience. The new large, 240-mm (10-in) touchscreen monitor with jog dial delivers intuitive navigation of machine controls. Operators can program joystick configuration and power preferences, and the new excavator recalls specific settings based on the unique Operator ID. Delivering all-day climate comfort, operators easily adjust internal cab temperature to the ideal setting using the new monitor.

Cab entry and exit is much easier with a new tilt-up left console. Featuring advanced viscous mounts, the M319 reduces machine vibration feed-back to the cab, reducing operator fatigue. Easy-to-reach controls increase comfort, while auto axle lock detects when the service brake must be locked or unlocked to reduce the number of actions required by the operator.

With available Deluxe and Premium cab designs, the Deluxe comes standard with a heated and air-adjustable seat, while the Premium offers a seat that is heated, ventilated and automatically adjusts.

Reduced maintenance costs

Offering double the filter life, the new M319 design synchronizes fuel filter change intervals at 1,000 hours. Fuel integrity and machine uptime reliability is improved with two filtration stages of particles in the diesel. The hydraulic system also features advanced filtration performance with anti-drain valves that keep the oil clean during filter replacement and a 50% longer filter life of 3,000 hours. Combined, these features lower maintenance costs.

Cat S∙O∙S fluid sampling extraction ports, daily maintenance points and engine oil dipstick can all be accessed from ground level to substantially improve maintenance efficiency. Operators easily track both filter life and maintenance intervals from inside the cab via the touchscreen monitor, facilitating maintenance planning.

Enhancing safety

Enabling the pushbutton starting feature with the unique Operator ID delivers an enhanced level of excavator security and operating safety for the new M319. Standard rearview and right-side cameras, along with large cab windows with small cab pillars, help to improve jobsite visibility for the operator. An optional 360◦ visibility system combines input from multiple cameras around the machine to give operators an unparalleled view of their surroundings. The excavator’s new flat engine hood design also improves visibility.

Ground-level daily maintenance points and upper-level service platform help to increase safety when working on the M319. A standard hydraulic lockout lever isolates all hydraulic and travel functions, while swing lock prevents the front linkage from moving during travel.

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.