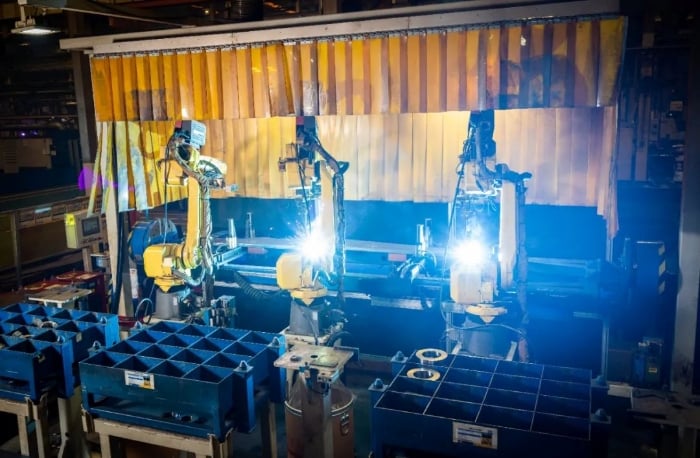

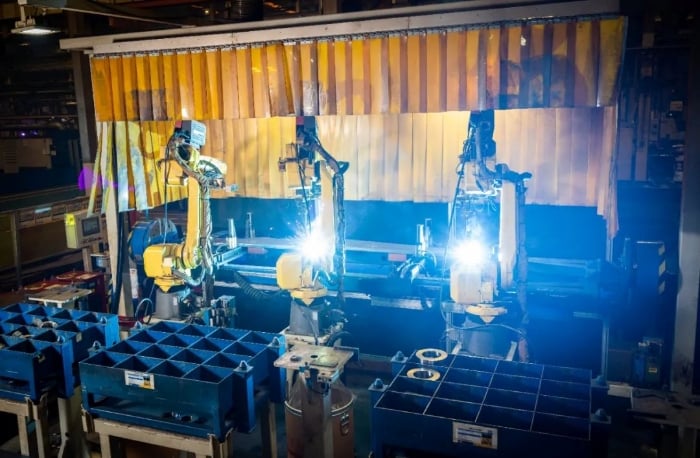

In XCMG’s production base, the days of welding dust flying everywhere are long gone. Robots have replaced humans in welding operations, exemplifying the beginning of XCMG’s green manufacturing movement.

“Ensuring the supply of green and low-carbon engineering equipment is an important step in promoting carbon neutrality and controlling carbon peaks,”

said Yang Dongsheng, Chairman of XCMG group.

Under the company’s long-term intelligent manufacturing plan, the production of XCMG loaders took the lead in the industry as early as 2012, introducing technologies such as robotic welding and automatic machine coating while integrating cloud computing, big data, and other information technologies into production. Internet access has covered 85% of production machinery and equipment.

XCMG has continued to apply big data in production, creating many industrial examples. Among them are the MES system and IOT platform, which achieved 85% coverage of network equipment, and the introduction of Sysweld welding simulation software, which has achieved a 90% rate of complete welding of loaders. Modern production methods, especially the application of big data, have led to significant improvements in product quality and production efficiency.

The smart meters for collecting data on energy-consuming equipment revealed that the instantaneous standby power of the robot is 3.13 kW, with an energy consumption ratio of 15%. We improved the automation control system and reduced it to 0.83 kW. Meanwhile, we strengthened the management of abnormal use of production power on the equipment and achieved a 17% reduction in unit energy consumption, saving over 6 million yuan per year.

The core of intelligent manufacturing is to reduce costs, increase efficiency, and improve quality to improve overall production with less raw material waste, thereby reducing carbon emissions.

We are committed to product-based market competition. XCMG aims to consolidate the fundamental characteristics of our products and improve efficiency with lower costs and lean manufacturing. Specifically, it plans to integrate people, machines, and materials; connect all aspects of production to collect data; apply the results to self-diagnose and improve production lines; and reduce waste in the production process.

Access is the primary link in sustainable supply chain management.

“The current market competition has changed from competition among enterprises to supply chain competition, and truly sustainable development is the only way to create a differentiated competitive advantage,”

said Yang Xi, head of XCMG’s supplier inspection team. XCMG is taking the initiative to create differentiation in supply chain competition by setting green access thresholds and green procurement standards to enforce the green production of enterprises in the chain.

To achieve the goal of carbon neutrality, XCMG has formulated a series of plans, including the “Supply Chain Allies Emission Reduction Action.” Every year, XCMG conducts sustainable training for suppliers more than ten times. In the last five years, XCMG has cooperated with suppliers to solve the 72 issues of green production since we launched the initiative of building a green supply chain. It has achieved more than 50 million yuan in energy-saving results while motivating suppliers to recycle and reuse resources, saving more than 3 million yuan on average per year.

The goal of achieving carbon neutrality and controlling peak carbon emissions will inspire the construction machinery manufacturing industry to transform. In the future, with XCMG’s continuous efforts in digitization, intelligence, and greening, we will continue to contribute to the sustainable development of the construction machinery industry and society.

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.