eFuels Alliance, is a Germany-based organization committed to the worldwide promotion and expansion of e-fuel production capabilities and their widespread application. The goal of the company is advancing and intensifying the production of synthetic carbon-neutral fuels. Last week, the results of a recent study published by Liebherr and Frontier Economics have been discussed during an online event, with a particular focus on the use of eFuels in the off-road sector.

The share of electric vehicles in the market for passenger cars and vans is increasing. However, electrification in aviation, heavy duty as well as in the maritime and off-road sectors is difficult or impossible to realize. Especially in the off-road sector, where vehicles are much larger and manufactured for extreme conditions, as well as in other applications ranging from chainsaws, mobile cranes, and excavators to snow ploughs, electrification is not always a viable option. An online event with eFuel producers Infinium and Nordic Electrofuels, as well as companies like DEUTZ, STIHL, Liebherr and Frontier Economics, provided detailed insights.

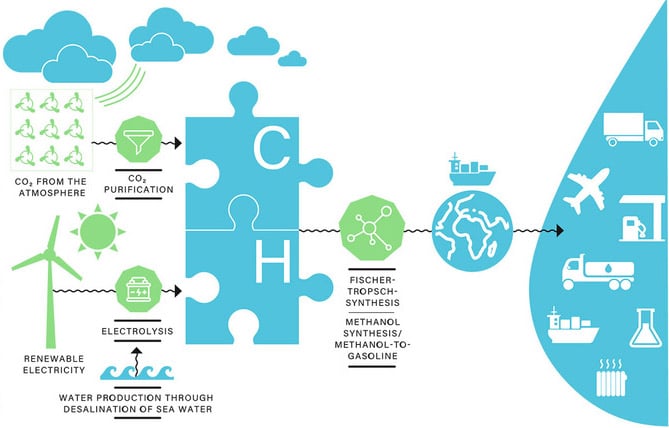

eFuels are climate-neutral synthetic fuels produced from renewable energy sources. For that only electricity generated from solar or wind, water, and carbon dioxide are required. The basis for the production of eFuels is the so-called power-to-liquid pathways, which are used to produce electricity-based liquid fuels using renewable electrical energy. First, hydrogen is produced from desalinated seawater by electrolysis using renewable electricity. The hydrogen is then synthesized with carbon dioxide using the Fischer-Tropsch process, developed back in 1925 in Germany, to produce a liquid climate-neutral fuel. This fuel can be used as an admixture in petrol, diesel or heating oil or as a pure climate-neutral fuel.

The urgent need to reduce fossil fuels

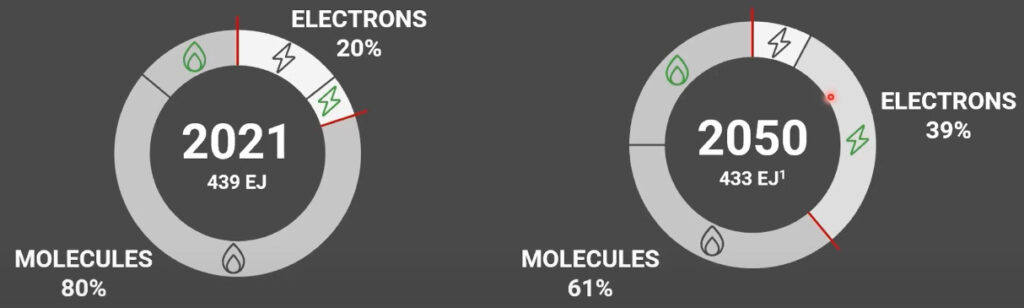

Today’s world energy consumption is highly depended on fossil molecules. If one divides the energy consumption in two variable one can see molecules on the one hand and electrons on the other hand. Electrons in today’s energy economy only contributes 20% and the dominant amount provided by fossil molecules, the 80%. While the ODA scenario introduced in 2021 announced ambitions and targets to reach 20% to 40% electron use of the entire energy consumption in 2050, the use of molecules will still be high at 60%, particularly fossil molecules will still be dominant.

Today’s world energy consumption is highly depended on fossil molecules. If one divides the energy consumption in two variable one can see molecules on the one hand and electrons on the other hand. Electrons in today’s energy economy only contributes 20% and the dominant amount provided by fossil molecules, the 80%. While the ODA scenario introduced in 2021 announced ambitions and targets to reach 20% to 40% electron use of the entire energy consumption in 2050, the use of molecules will still be high at 60%, particularly fossil molecules will still be dominant.

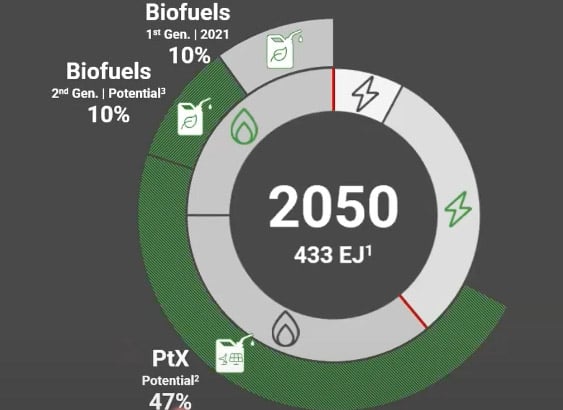

One answer to this problem could be a renewable fuels potential, as represented in the image, with 10% of first-generation biofuels and 10% of second generation biofuels of the world’s energy consumption. But due to limited feedstocks, these capacities are limited and that is why eFuels or PTX products have to play a decisive role corresponding to 47% of final energy consumption.

Off-road sector challenges

“The challenges in the off-road sector go beyond the replacement of today’s diesel vehicles, respectively the installation of powerful charging stations. At the same time, the sector is of great importance to our daily lives. Whether it is the construction industry, forestry, mining or agricultural equipment, in some cases these machines are used around the clock for years and perform specific tasks in isolated and difficult settings. Here in particular, technologically smooth operation is fundamental to ensuring our supply of raw materials and the future of the industries. There is a complex need to understand and match the different drive options of these applications with the specific work requirements.”

said Dr Monika Griefahn, Chair of the eFuel Alliance.

“The off-road sector, because of its versatility, highlights the strengths of a technology-open approach and shows how different the path to a fossil free future can be. This sector is geared towards individual requirements and consistently tries to replace fossil fuels with CO2-neutral fuels in a timely manner. This is an important path that we need in all sectors”

says Ralf Diemer, Managing Director of the eFuel Alliance.

A recent study by Frontier Economics on behalf of Liebherr, one of the world’s largest construction machine manufacturers, underlines the advantages of a technology-open approach. The off-road sector, like all other industries, is committed to becoming climate neutral.

“The regulatory framework of the European transport sector focuses purely on tailpipe emissions. Thus, only drivetrains that do not emit CO2 during operation are considered climate-friendly. The study examines various technology paths, whereby it becomes clear that a technology mix, the combination of battery-electric, hydrogen-powered as well as eFuels-powered engines, delivers the best result when it comes to our climate goals. A consideration of the entire life cycle must be the benchmark for any application in the transport sector.”

says Diemer.

Recently, the EU Commission proposed a voluntary system (CountEmissionsEU) in its Green Freight Package that would transparently map the CO2 emissions of the transport chain:

“While we advocate this holistic approach in many areas, it is to be welcomed that the Commission does not focus on the emissions that occur at the tailpipe but looks at the entire cycle when considering the entire transport chain. This approach allows real CO2 emissions reduction. Therefore, this approach needs to be adopted in the currently discussed CO2 fleet regulation for heavy-duty vehicles as well and to enable climate-friendly renewable fuels to be taken into account, e.g. by means of a carbon correction factor. Otherwise, a ban on internal combustion engines for heavy duty vehicles will have a negative impact on the off-road sector, because many components such as engines or transmissions are identical in construction.”

No unique solution for off-road applications

Andreas Plumpe, DEUTZ’s methodology development, said that off-road applications are very different, they have a big variety in term of energy demands for duty cycle.

On one hand there are light duty applications like taylor handler, towering tractor on the airport, forklifts are applications that have the best preconditions to be electrified. On the other hand there is heavy duty equipment like wheel loader, dumpers, tractors, mobile crane etc. There are huge energy demands, and the size of the batteries were just not been suitable for these applications apart from those machines being operated in areas that are very rural and do not have access to energy infrastructure.

In conclusion the applications are very versatile and that is why there is no on-fits-all solution for non road mobile machinery.

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.