Off-highway machines – such as excavators and tractors – are some of the largest and most powerful machines in the world, requiring huge amounts of power and generating vast amounts of pollution per machine. Manufacturers of off-highway machinery have developed electric models to reduce greenhouse gas emissions and other pollutants. These machines – given their size and operating hours – are difficult to electrify, as they require very large batteries and regular access to a grid connection.

To date, adoption has been very slow, even in markets that are relatively progressive when it comes to reducing emissions from construction. One of the key challenges is for electric machines to operate for the same length of time as their diesel-powered equivalents. Unlike passenger cars, off-highway machines may be in use for over 8 hours a day and, in many cases, much more.

To get the same performance from an electric machine requires a very large and very expensive battery. Not only does this make the machine unaffordable, even allowing for the lower cost of electricity versus diesel, it can be hard to design machines with very large batteries (where do they go on the vehicle?). It also takes a very long time to recharge the battery, taking the machine out of operation and doing the job it is required to do, costing the operator money.

But is there a solution that would both cut the cost of the machine and speed up the charging time?

Is anybody developing battery swapping solutions?

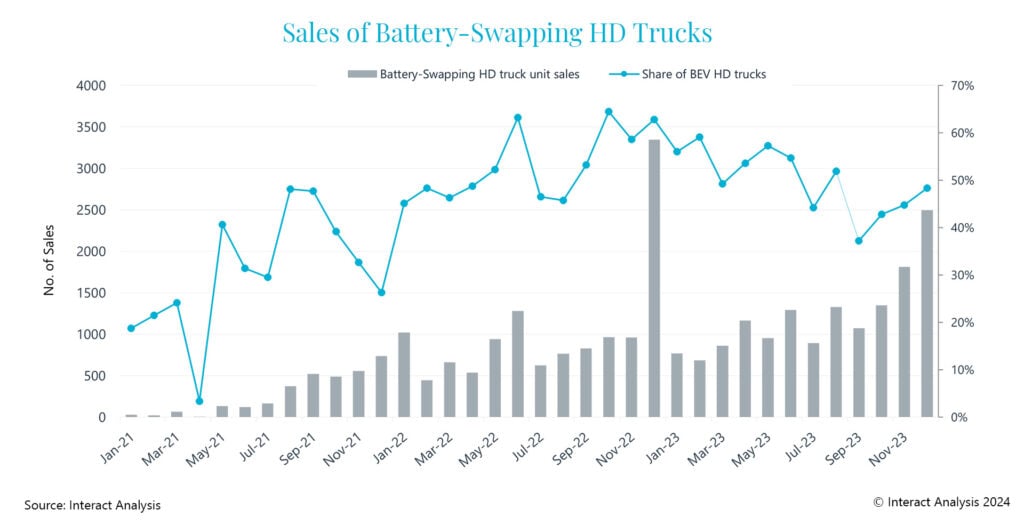

Battery swapping is not a new concept. In the passenger car market, battery swapping has a murky past (anybody involved in electromobility will remember the failure of Better Place), although Chinese car OEMs are trying to create an ecosystem. In the heavy-duty truck market, there is a developing market in China where several thousand trucks already support battery swapping.

For off-highway, there are tangible green shoots of battery swapping solutions that might help to drive wider adoption of electric machinery, including:

Sandvik produces a battery-electric underground loader that supports battery swapping. The vehicle’s battery pack can be swapped in 5 minutes with no need for the operator to leave the vehicle. This allows the battery to be recharged while the vehicle is in use and minimizes the time that the machine isn’t hauling rock.

Komatsu and Honda have jointly developed a micro-excavator – the PC05E-1 – that is an expanded version of the PC01E-1. It is powered by the swappable Honda Mobile Power Pack e (a small, 1 kWh pack) that can be exchanged by hand. This type of machine is suitable for small groundwork and, because of its size, is highly manoeuvrable.

ZQuip – a newly formed Moog subsidiary – has a battery swap solution that can be integrated into existing diesel machinery to convert it to electric. ZQuip energy modules are a battery-electric solution that is machine and industry-agnostic. The swappable and modular system creates a sustainable energy solution for job sites as both a zero-emission powertrain for machinery and an energy storage system that can discharge electricity to other machinery or equipment at the job site (BESS). ZQuip energy modules provide a cradle-to-grave battery-electric solution for construction sites.

The Drever 120 is an autonomous ag machine built by Traktorarvid Arvid Örde and RISE Research Institutes of Sweden. It features a modular battery swapping system to support longer field operation.

Webasto and Dutch company Electric Construction Equipment (E.C.E.) collaborated in 2020 to convert Doosan excavators to operate using swappable battery packs. ECE is a part of Staad, a distributor of Doosan equipment. The battery packs from Webasto are modular and each excavator has two swappable ‘powerboxes’ that have 140kWh of capacity.

AGROMEC in the Netherlands has developed a battery swapping solution for agricultural tractors. The tractor has a relatively small onboard battery – 70 kWh – which provides enough power for short, light work and for getting to a battery pack. A swappable 140 kWh pack can be added to the front of the tractor, enabling longer operational performance. The pack is made by ECE/Webasto and several of these tractors are already in operation on farms and construction sites in the Netherlands. Electrification of ag equipment is challenging and, in fact, electric solutions may not be the route the industry decides to go. However, it is just possible that a standardised battery swapping solution might help to really drive adoption and convince farmers to make the swap.

The advantages to battery swapping in off-highway

Building machines with swappable batteries has a number of advantages. Battery packs can be made smaller or even eliminated completely from the machine, substantially reducing the upfront cost and spurring wider adoption – 38% of the cost of an electrified off-highway machine is the battery. Operators can manage costs by selecting the number of packs they need for a job, rather than purchasing a very large battery when they rarely need to use all the stored energy. Furthermore, the problem associated with charging – having the vehicle non-operational – is removed since a pack can be effectively swapped in 5 minutes. Battery packs can be used for grid storage when not in machines – either overnight or in off-seasons – and this provides operators with an additional revenue stream. And, finally, this may well prove to be a lucrative source of income for rental companies, as they can provide a battery pack service for users requiring additional capacity.

Disrupting the off-highway market with battery swapping

In June of last year, I wrote about how the construction equipment sector could be disrupted by electric construction equipment. One of the key enablers of this is battery swapping, pushing down the cost of machines and solving one of the problems associated with charging.

If anything, that need for disruption has grown stronger, but deployments of electric equipment are still relatively low. With concerns growing about the cost and availability of biofuels and efuels, low and zero-emission off-highway equipment may need to become electric to meet stringent emissions legislation.

Although it is a very nascent market – certainly not one that is driving any significant revenue right now – battery swapping for off-highway has potential and we wonder how long it will it be before we see this become more commonplace on construction sites and farms.

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.