At Intermat, the Wirtgen group will be presenting a representative cross section of its portfolio for the entire road construction process chain. The company’s focus will be on environmentally compatible technologies, solutions and applications that make decisive contributions to the reduction of CO2 emissions in the construction industry.

The Wirtgen Group always considers the entire construction site and, with its Production Systems, thinks in terms of its customers’ specific needs – from project planning and execution to end-to-end documentation of the construction site. In the course of this, digitalization will be an essential driver for greater sustainability and higher precision.

Trade show premieres for the French market

Among the highlights at the show are two exhibits that are being shown for the first time at an industry fair in France. With the MOBIREX MR 100(i) NEO / NEOe mobile impact crusher, Kleemann presents the first member of its new family of compact crushers. The machine is efficient, powerful and extremely flexible – and the NEOe version makes all-electric operation a viable option.

Battery-electric drive systems and hydrogen-fuelled burners

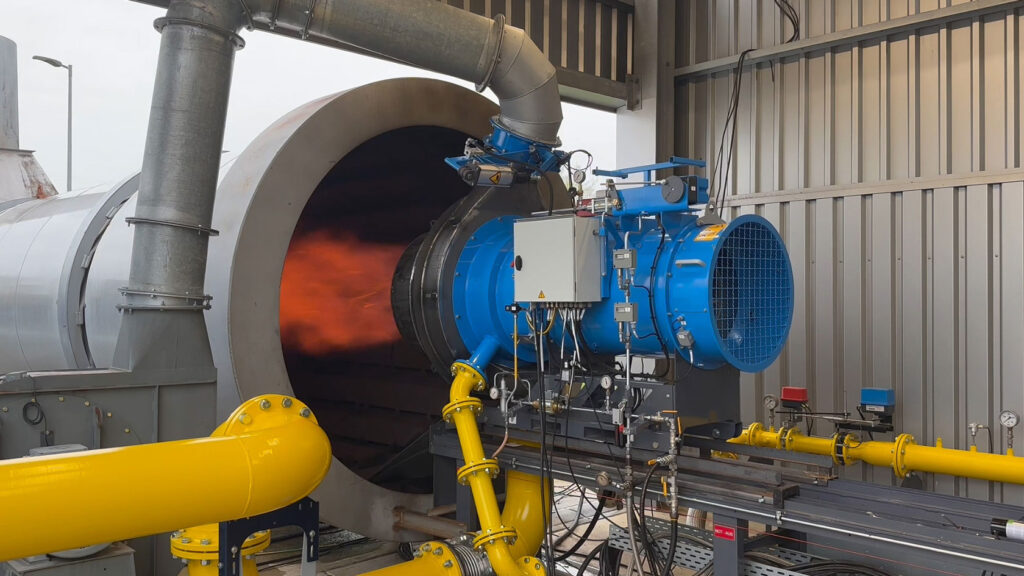

The new battery-electric tandem rollers of the HD CompactLine from Hamm provide low-noise compaction with zero local emissions and deliver the same compaction performance as their combustion-engined counterparts. The roller manufacturer will be presenting the 2.7 t HD 12e in Paris. The focus is also on sustainability when it comes to the latest generation of burners from Benninghoven. For the first time, burners can now be fuelled by 100% green hydrogen – a further milestone on the way to even more sustainability in the road construction process chain. The particularly small, light and agile MINI 500 and MINI 502 road pavers from Vögele are ideal machines for the realization of paving tasks in even the tightest spaces on construction projects. The electrically-powered MINI 500e and MINI 502e models will be available later this year.

Recycling also possible for round-shank picks – Wirtgen Group nominated for the Innovation Award

With their submission titled ‘Recycling of Cutting Tools’, the Wirtgen Group and its system-partner Betek are among the three nominees for the Intermat Innovation Award in the category ‘Roads, materials and foundations’. The partners worked together on the development of a method that enables the recovery of carbide and its reuse in the production of new cutting tools – for instance for Wirtgen cold milling machines. The method not only conserves valuable resources but also reduces the carbon footprint of the production process.

Source: Wirtgen Group

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.