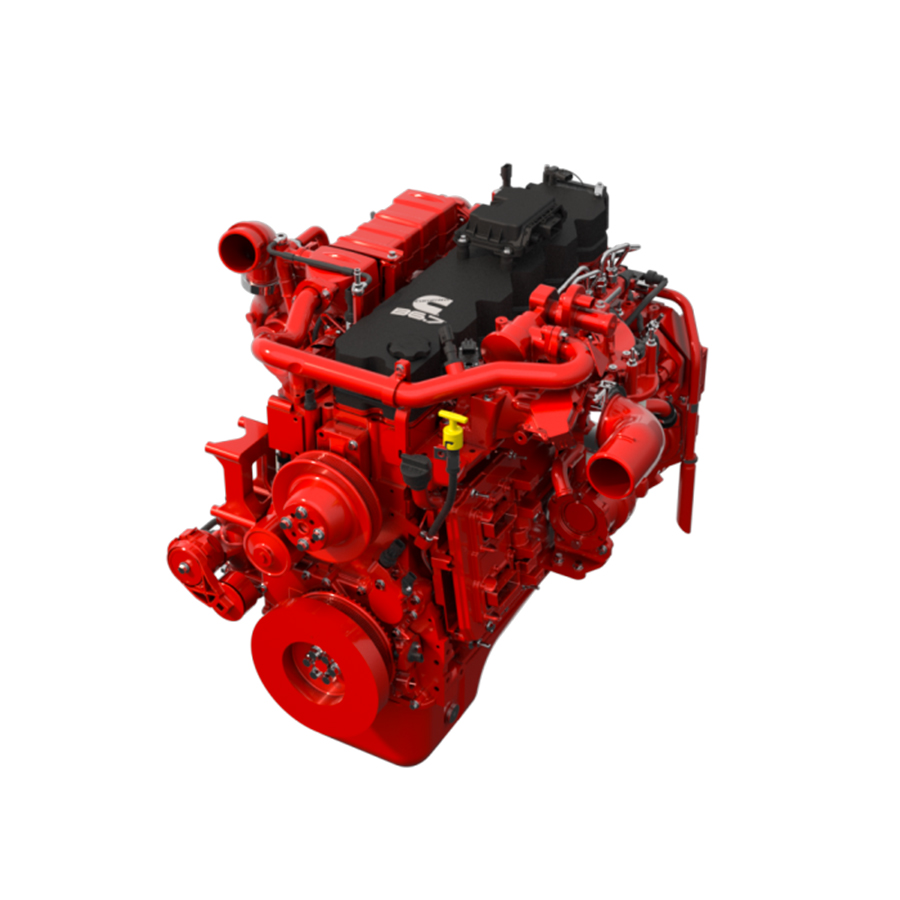

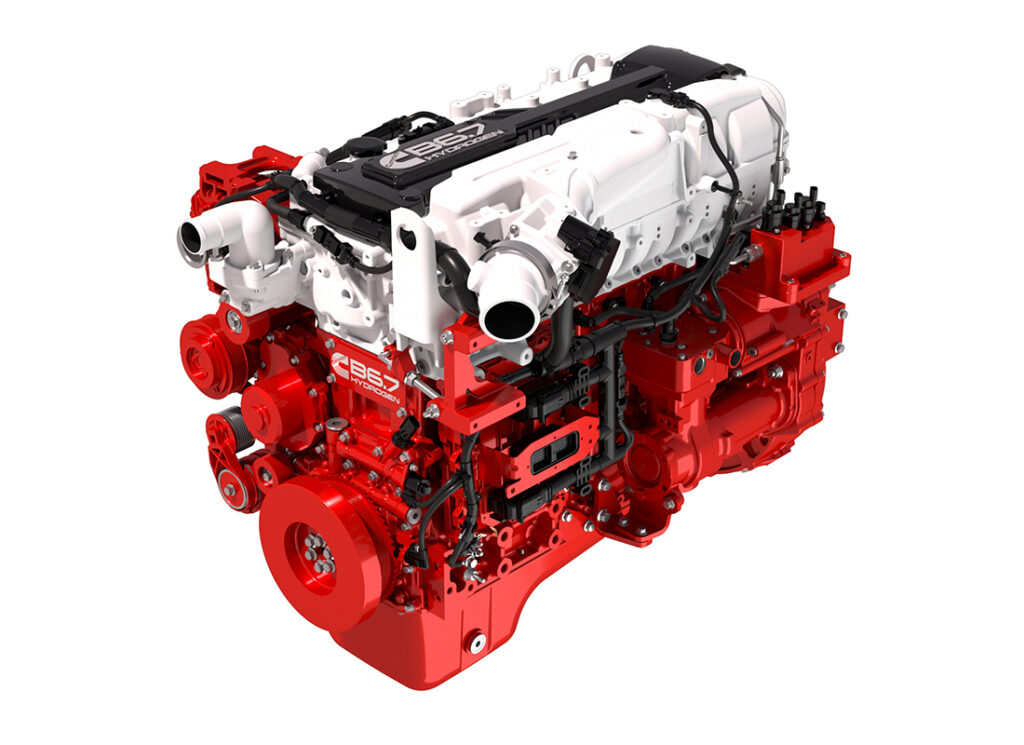

At Intermat, Cummins will showcase its next-gen B6.7H hydrogen engine to the construction industry for the first time. Aimed at a wide range of off-highway machinery, the B6.7H has a top rating of 290 hp (216 kW) and a peak torque of 1200 Nm targeted for Stage VI/Tier 5.

“Continued investment in the development of our internal combustion engines remains a key part of the company’s strategy towards Destination Zero. We are targeting further improvements in performance and efficiency alongside compatibility with cleaner fuels. This must be achieved without impacting operations, weight, or uptime.”

said Antonio Leitao, Vice President Cummins’ Off-Highway Engine Business.

Following on from the agnostic 15-litre engine display at last year’s Conexpo event, Cummins will exhibit the new B6.7 engine platform with the same capability. This design enables a consistent mounting and space claim for clean diesel, biodiesel, natural gas, and hydrogen fuels. The main engine block remains the same with the head and the fuel system being the key changes. They can be installed in the same equipment as today’s diesel while also using the same transmission, cooling systems, and hydraulic systems, reducing complexity for equipment manufacturers and their customers. Maintenance practices and costs are also comparable to diesel engines.

“Our current B6.7 is a leader in the market, and it is important that we keep developing its capability and value for our customers as well as reducing the environmental impact. The new B6.7H hydrogen engine will fit in today’s machines, work with today’s transmissions and hydraulic systems, and integrate into the industry’s service networks and practices.”

added Leitao.

Cummins hydrogen-powered combustion engines will provide sustainable solutions that can meet the demands of the most challenging applications. Hydrogen combustion is robust for the extreme operating and environmental conditions witnessed in construction and quarrying applications.

Also on display at Intermat will be the on-board fuel storage, a critical component in the adoption of hydrogen power. Hydrogen needs to be compressed into the available space to store enough to meet machine duty cycle requirements. Cummins’ joint venture with NPROXX, an expert in high-pressure hydrogen storage for both stationary and mobile applications, will be supporting OEMs and their product integration process. The storage tanks on show will have up to 700-bar pressure capability to maximize capacity and operating range.

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.