Parker Hannifin, the global leader in motion and control technologies, today announced the launch of its innovative VA130 mobile valve, completing the Parker VA Series valve portfolio.

The VA130 delivers industry-leading performance, exceptional controllability, and enhanced energy efficiency. Precision-engineered using high-grade materials, this valve offers flexibility and customization, enabling seamless integration into both simple and complex hydraulic systems across a broad range of applications.

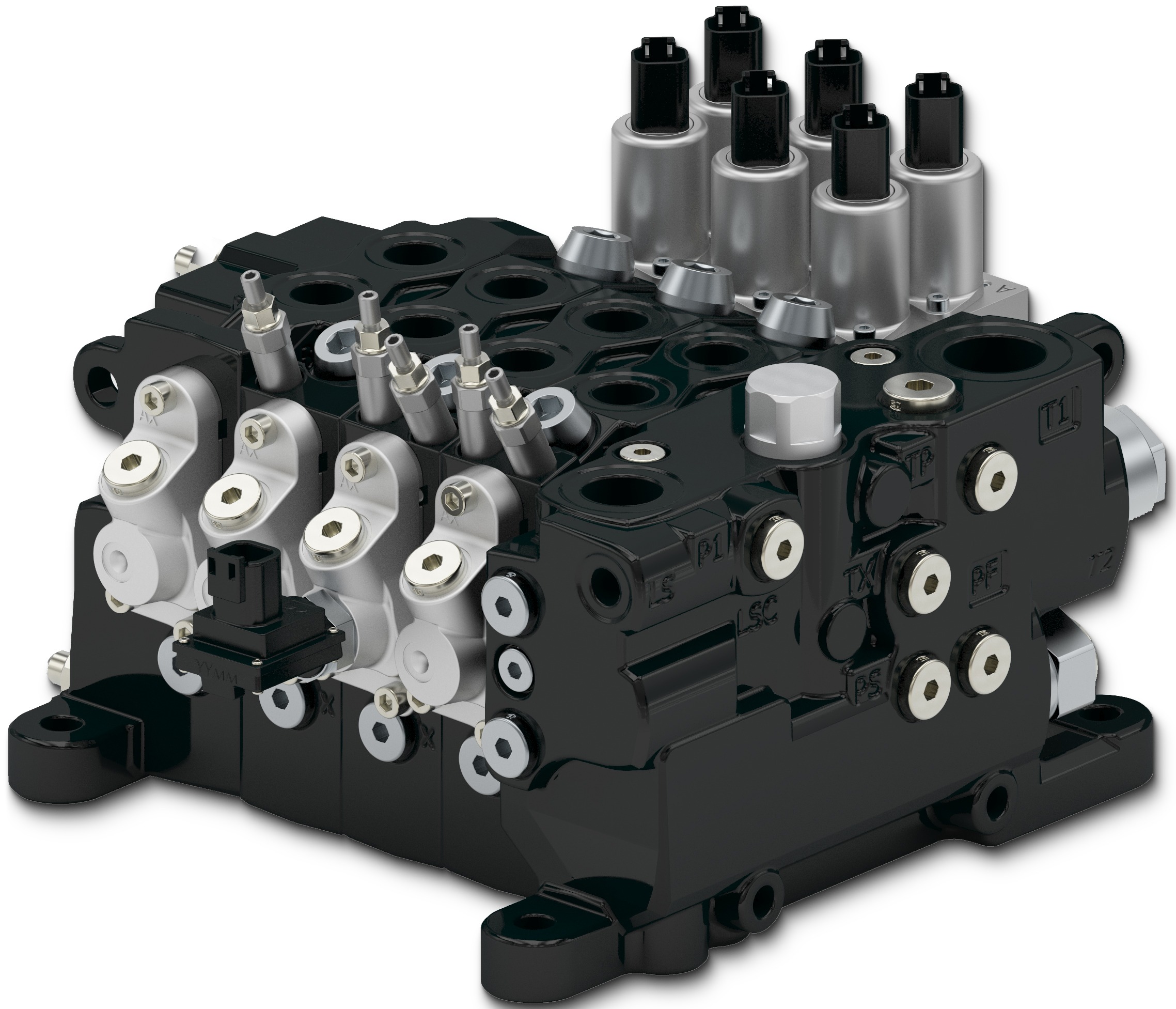

As part of the VA Series, the VA130 is combinable with the VA450 and VA300 making it an ideal valve for compact valve solutions in machinery where there are varying needs in terms of flow. Combining the modularity and an extensive variety of valve functionalities and combination options, Parker provides customers with optimized solutions for their specific machine needs. The valve’s design incorporates function-adapted spools, pressure compensators, and load signal pressure limiters, all developed through Parker’s deep expertise in load-sensing technology. This innovative approach significantly reduces energy losses while boosting productivity, marking a new standard in energy-efficient hydraulic control.

The VA130 offers multiple actuation methods — hydraulic or electrohydraulic — with optional manual lever control available in any combination within the same valve.

This flexibility is complemented by the ability to combine the VA130 with tailor-made function manifolds, crafted from Parker’s comprehensive product range, to fully customize auxiliary function control. This integration reduces the number of system components, simplifies hydraulic system design, and enhances overall reliability and ease of maintenance.

The VA130 valve also incorporates advanced features designed to fit harsh operating environments. These include pre-compensated, load-independent flow control with function-adapted main spools for precise machine operation, LS pressure limitation, active tank gallery refilling, and emissions reduction technologies. Performance monitoring is facilitated through dedicated measuring points and Parker’s spool position sensors, available in both analogue and digital formats. Parker’s unique online configurator further streamlines development by providing instant access to automatically generated code reports, schematics, spare part lists, and 3D/2D models.

Targeted at key industries such as forestry, construction, material handling, and mining, the VA130 is ideally suited for a wide array of applications including forwarders, forestry harvesters, forest cranes, harvesting heads, mining machines, drill rigs, loaders, dump trucks, excavators, forklift trucks, material handling cranes, and reach stackers.

Copyright 2017-2025 All rights reserved.

Copyright 2017-2025 All rights reserved.