Innovation has always been one of the pillars of the Merlo Group; even in the most challenging moments of its history, in fact, Merlo has continued to invest and believe in technological evolution as a fundamental point to continue to evolve, to move forward. This has led to an internationally recognised technological leadership and over 80 registered patents.

2020 is no exception, this year Merlo’s evolution continues and has led to the development of the first electric off-road telehandler: the e-Worker. As proof of the innovative system adopted by this revolutionary range, numerous international awards have been received, starting with the gold medals received in Verona for the “Samoter Innovation Award” and in Paris at the “Grand Prix Matériel” awarded by Chantiers de France and DLR.

Now, a further award for the technology developed has added to the list of the Cuneo-based company: the “EIMA International 20/21 Mentions” for the “Integrally electric transmission on eWorker”.

The innovative transmission introduces a software that controls both the torque and the rotation of the individual motors placed on the wheels, in order to guarantee the correct speed of each single wheel in all possible operating conditions of the telehandler. Moreover, in case of front internal wheel slipping, the other wheels will always guarantee the required rotation speed and the torque necessary for the correct performance of the activity.

In order to exploit the full potential of the electric units, but at the same time limit consumption in continuous operations, the machine is equipped with a control system that monitors the instantaneous and average energy consumption of the vehicle.

New e-worker electric range

The ability to handle material safely and with maximum ease of use has always distinguished Merlo telescopic handlers in agricultural, construction and industrial applications, without differences. The continuous search for specific innovative solutions and technologies, in order to satisfy the needs of customers, has led Merlo to the creation of an exclusive range of telescopic handlers with small dimensions and respectful of the environment as they are 100% powered by electric batteries.

This revolutionary range combines the performance of a traditional telescopic tractor with the fuel consumption and reduced dimensions of an industrial forklift truck. According to the standard cycle of the EN16796-1/-4 standard the consumption is of 6 kWh/h, comparable to that of industrial forklift trucks with 2 drive wheels and small tyres. e-Worker, on the other hand, features 4 drive wheels, large agricultural tyres and is designed to work off-road.

The top features of this range are therefore: the complete reduction of noise levels and polluting emissions, increased manoeuvrability in confined spaces and the drastic reduction of operating costs compared to similar models equipped with heat engines powered by diesel fuel. The new range is designed to be used in closed environments such as: stables, warehouses, material sheds, industries and underground applications; it also guarantees operation and traction even in off-road situations to meet the needs of municipalities, agriculture, construction and landfills.

The advanced software makes it possible to monitor battery status, residual charge information, transfer speed and all work parameters, displayed in real time on the on-board computer in the cab.

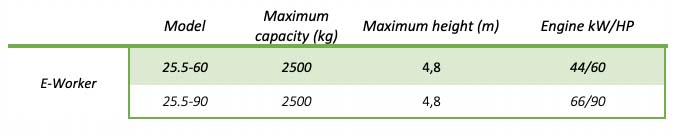

The range consists of two models.

- E-Worker 25.5-60 – 2 driving wheels

- E-Worker 25.5-90 – 4 driving wheels

The 6 winning points:

- Safety without compromise, the E-Worker combines extreme compactness with safety guaranteed by a traditional telehandler.

- Power, impossible to stop, this innovative range offers superior traction even in off-road situations, overcoming slopes of over 40%.

- Comfort, the best workplace thanks to the easy access and the generous size of the cabin with 785mm of maximum width and record-breaking visibility.

- Maneuverability, agile in every situation thanks to the exceptional steering angle of the rear axle and the reduced dimensions, in addition the load remains always within the size of the machine.

- Versatility, fully compatible, the Merlo – ZM1 interface allows compatibility with the wide choice of Merlo equipment. It’s available also with towing homologation up to 6,000kg.

- Efficiency, even greener, 100% electric managed machine. The battery pack is able to power the hydraulic pump for the movements of the arm and the electric motors for traction and movement of the machine.

Source: Merlo

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.