Bandvulc, the UK’s manufacturer of retread tyres for commercial vehicles, (a subsidiary of Continental) unveils the latest next-generation tyre in their Wastemaster range.

The new Wastemaster 5 state-of-the-art tyre is launched after extensive testing and field trials and marks the 5th generation of thepopular Wastemaster tyre product which has been developed, tested and produced at Bandvulc’s Ivybridge factory in Devon. The Wastemaster 5 will replace the Wastemaster III, a proven product in the waste sector that has been around for more than 20 years.

Tony Mailling, Operations Director at Bandvulc comments;

“Over the past two years we have seen strong growth in the waste and construction market, which is buoyant at the moment because there’s lot of infrastructure and housing being built. Our understanding of UK roads and vehicle operating conditions has been a key tool in our market research for this exciting new product. The waste collection market is changing; waste is more segregated now with more collections a week and the collection vehicles are operational in all weather conditions such as sleet, snow, or heavy rain. Our roads can be subject to a lot of debris especially in urban areas so our tyres

need to be equipped with features to perform for the driver in all conditions”.

Specialist waste vehicles providing kerbside waste collections and operating in recycling sites require a hardworking tyre. Tyres in this industry can be subject to sidewall damage from kerbing, tread damage from stone trapping, chip and chunking from rough surfaces, all of which can result in premature removal and not achieving the full life of the tyre.

Specialist waste vehicles providing kerbside waste collections and operating in recycling sites require a hardworking tyre. Tyres in this industry can be subject to sidewall damage from kerbing, tread damage from stone trapping, chip and chunking from rough surfaces, all of which can result in premature removal and not achieving the full life of the tyre.

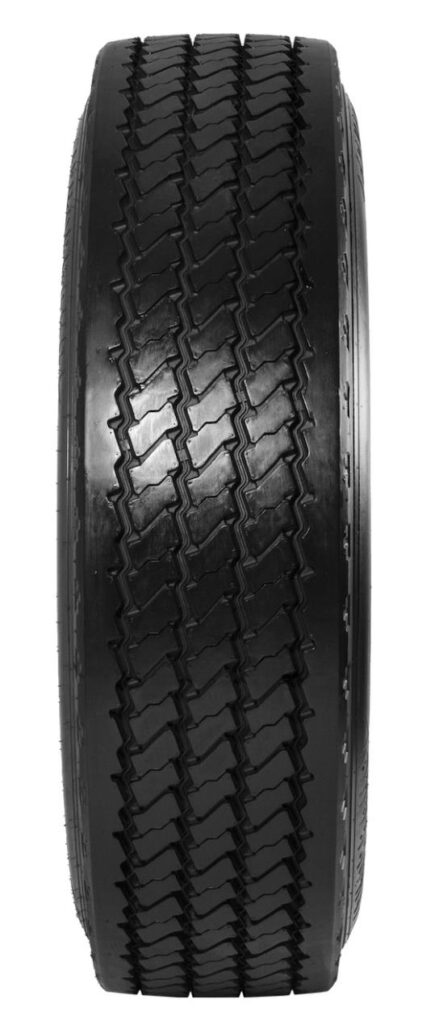

The WM5 retains Bandvulc’s pioneering ARMORBAND sidewall technology which offers an additional protective layer of rubber compound on the mid to lower sidewall of the tyre. This tapered protective band adds additional protection against sidewall scrubbing, protects against damage and prolongs the life of the tyre. The tread design on the Wastemaster 5 has also had a complete redesign to offer the latest features for this sector, offering wide zig-zag grooves for excellent displacement of mud and water, stone ejection features, stepped tread blocks and additional deep pocket sipes providing excellent traction and grip in severe conditions. The Wastemaster range has continued to evolve with the introduction of a High load version of the Wastemaster II tyre in 2019 and the 295/80R22.5 Wastemaster 5 is also available in a High Load option.

James Griffiths, Technical Manager for Bandvulc adds; “The Wastemaster 5 also bears the Three-Peak Mountain Snowflake (3PMSF) symbol which indicates the tyre meets required performance criteria in snowy conditions and provides improved snow traction beyond a standard M+S branded all-season tyre. It was important for Bandvulc to make this investment in the tyre as it gives our customers peace of mind that the tyre will offer superior traction in all UK conditions. It also makes the tyre very flexible if we wish to sell it in Europe where 3PMSF is mandatory in some countries in the winter months.”

“We’ve collated feedback from the drivers who have trialled the Wastemaster 5; they are experts on how it handles and how the tyres grip. The solid shoulder design and wider contact area, provides stability control and excellent handling characteristics. The feedback we’ve had from testing so far has been extremely positive.”

Tony Mailling adds; “At Bandvulc one of the things that is important to us is working closely with customers and creating bespoke products to meet their unique demands. Launching a new tyre says a great deal to both our customers and our workforce about our investing in the future because it costs money to develop new tyres. We’re very proud of this new tyre and of the teamwork and collaboration that our people have demonstrated in order to make it happen”.

In 2021, Bandvulc celebrates 50 years of retreading, a significant milestone in its journey of sustainable retreading. Over the years, the company has grown and evolved to become the UK’s leading retreader, producing the best premium retread tyres at its purpose-built plant in Devon. Today, as a subsidiary of Continental Tyre Group Ltd. Bandvulc produces a retread tyre every three minutes and its proven range contains more than 100 different tread patterns and sizes, along with specialist applications for its customer portfolio which includes many household names.

Bandvulc’s ethos has always been to produce the safest, most economical and environmentally friendly retread-tested and quality assured to deliver the best performance to its customers. Sustainability is at the heart of Bandvulc’s operation: with each retreaded tyre 68 litres of oil, 30kg of rubber, 20kg of steel and 60kg of CO2 are saved against a new tyre.

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.