As part of the company’s award-winning DL-7 series, Doosan has launched the new DL420CVT-7 Stage V compliant wheel loader equipped with a Continuously Variable Transmission (CVT). With a maximum bucket capacity of 4.5 m3, the Doosan DL420CVT-7 wheel loader is intended to meet a wide range of material-handling needs from loading and transporting granular material (such as sand or gravel) to quarrying, mining, construction, demolition, industrial, waste and recycling applications.

A CVT transmission is the result of a permanent combination of a hydraulic technology and a mechanical technology which provides a smooth and continuous speed variation. The CVT design combines the benefits of a hydraulic mechanical transmission and a hydrostatic transmission in the same machine. It allows the DL420CVT-7 to automatically transition from hydrostatic power at low speed to the mechanical system to operate at higher speeds.

By combining the two types of transmission, the CVT technology ensures high loads can be carried at low engine speeds with high dynamics for an optimum wheel loader operating cycle. The DL420CVT-7 therefore provides an increase in machine performance for operators working in digging, loading and lifting applications. For most tasks, operators will utilise the hydrostatic part of the transmission, which offers greater fuel efficiency in low-speed applications. The combination of the two transmissions is automatic and fully transparent for the operator.

Up to 15% Additional Fuel Savings

The complete driving range, forwards and in reverse, is controlled by the CVT system. Low engine speeds ensure a high efficiency and the highest driving comfort irrespective of the traction speed. The power splitting continuously variable technology facilitates moving off softly and hydraulically. Furthermore, with the CVT, a fuel saving of up to 15% can be achieved.

With an output of 240 kW (326 HP) of power at 1800 RPM, the Scania DC09 engine in the DL420CVT-7 provides generous torque at low RPM and meets Stage V emission regulations without the need for exhaust gas recirculation (EGR), through the use of selective catalyst reduction, diesel oxidation catalyst and diesel particulate filter (DPF) after-treatment technologies. The soot cleaning cycle on the DPF has been improved to over 6000 h and the operator is fully informed about the status of the DPF via a soot level indicator on the new touchscreen display in the cab.

New Award-Winning Design

The new DL420CVT-7 features the same award-winning external design common to all models in the DL-7 series, creating a three-dimensional effect with an innovative cover shape and a vibrant, dynamic image for the range. It has already received great acclaim globally, winning Germany’s 2020 iF Design Award, one of the world’s top three design awards and the ‘Best of the Best’ category in the Korean PIN UP Design Awards.

Increased Productivity and Versatility

The Z-kinematic lift arm on the DL420CVT-7 delivers high breakout forces and lifting capacities, especially for heavy materials, and a large dump angle for efficiently unloading sticky materials. An optional high lift arm is available where higher dump heights and increased versatility are required. Doosan is also offering a wider choice of options to provide more work tools for a better match with applications, further increasing output.

Like all DL-7 wheel loaders, the DL420CVT-7 loader has smooth and responsive hydraulics and auxiliary hydraulic connections. It is equipped as standard with a 3rd spool valve with settable flow and detent function, providing a constant flow for hydraulically driven attachments. Operators can easily and comfortably control hydraulic attachments via the proportional switch on the joystick. Various bias and radial tyre options are also available from leading global manufacturers, to cover the widest possible range of conditions and applications.

In addition, the new wheel loader can be ordered with a heavier optional counterweight, depending on the application.

Excellent Operator Visibility

The new cab on the DL420CVT-7 offers a greatly improved field of vision for the operator, with blind spots around the cab minimized and a 14% larger glass window area compared to the previous DL-5 model. The DL420CVT-7 wheel loader also offers the option of electrically adjustable rear view mirrors for added safety. Full LED working lights are installed on the cab (four on both the front and rear as standard, with the option of six each at the front and rear). For higher pedestrian safety, the LED lights on the rear onnet have an automatic strobe function to indicate when the wheel loader is reversing.

An air compressor with air blower is available as an option – fitted in the cab for easy access, this is a powerful tool that can be used to clean the cab whenever necessary.

New Spacious Ergonomic Cab Design

Inside the cab, the DL420CVT-7 provides significantly enhanced operating comfort, an enhanced steering system and advanced electronic controls. Using the new Doosan Smart Key system on the control panel in the cab, the operator can start the machine using a keyless device, helping to prevent machine theft. The Smart Key system provides remote door control, door lock and unlock, door release, searching and other functions. The control panel also includes two USB sockets.

The new cab has a Grammer Actimo XXL seat with fully adjustable horizontal and vertical suspension settings, a pneumatic lumbar function and seat heating as standard. There is a 3-point safety belt with alarm icons on the new Doosan Smart Touch 8 inch touchscreen monitor and on the gauge panel, which features a new layout and anti-reflective glass.

The new EMCV (Electric Main Control Valve) joystick fully integrated in the armrest is another standard feature in the cab, providing the operator with smoother and precise controllability of the lift arm and attachments on the wheel loader. Features available via the EMCV system include Automatic Return-to-Dig, Bucket Tilt Kick-out and the Bucket crowd stop position and shock prevention for higher operator comfort.

Designed to give the operator more precise control with a shorter lever stroke, resulting in less fatigue, the sensitivity of the ergonomic joystick control can be set and altered according to operator preferences using the new Doosan Smart Touch touchscreen monitor. User-friendly and easy to read in all conditions, the new touchscreen provides all the important settings and information the operator needs in one place.

Included in the information at the operator’s fingertips on the touchscreen is the feed from the rear-view camera, the weighing system, the HVAC controls (heating, ventilation and air conditioning), Radio & Bluetooth devices (music streaming, hands-free) and the operator help function.

Overall, the redesigned interior offers a much larger, quieter and more comfortable operator environment, which improves safety and productivity and helps the operator work with high concentration. The operator also has increased leg room, an enlarged storage area and cool-box position and an improved air conditioning system (with optimized air circulation).

Higher Performance

The LIS (Load Isolation System) provides a smoother ride and higher comfort for the operator, as well as higher productivity due to improved stability when the wheel loader is moving. The lift arm is cushioned by a hydro-pneumatic accumulator linked to the lift hydraulic system, acting as a shock absorber. The benefits include reduced cycle times, higher performance and better fuel efficiency while carrying out load and carry applications.

With heavy duty HDL axles as standard and enhanced traction with Differential Hydraulic Lock (DHL), the DL420CV-7 wheel loader operates exceptionally, especially in high-load environments. The differential hydraulic 100% lock can be engaged at full torque automatically without any action from the operator.

Optional independent oil cooler circuits for the front and rear axle ensure low oil temperatures, provide oil filtration and extend the lifetime of axle components, especially for demanding applications, such as long distance load and carry in high ambient temperature conditions.

Improvements have been made throughout the powertrain, to provide operators with best-in-class driveability and faster driving, reaching the 38 km/h maximum speed quickly and safely.

Full 3-year/5000 h Warranty as Standard

The upgraded hydraulic system and major parts ensure greatly improved durability and maintainability. Providing increased peace of mind for the customer, the high reliability and quality of the new DL420CVT-7 wheel loader is backed up by a standard full 3 year/5000 hour warranty.

DoosanCONNECT Fleet Management System as Standard

The DL420CVT-7 wheel loader is factory-installed with the latest DoosanCONNECT TMS2.0 state-of-art wireless fleet monitoring system. The DoosanCONNECT system is a tool designed specifically for the Doosan range, providing comprehensive information about machine performance in a dual mode (satellite, Mobile network).

The DoosanCONNECT system offers a web-based fleet and asset management solution which is very useful for managing the performance and security of machines and promoting preventative maintenance.

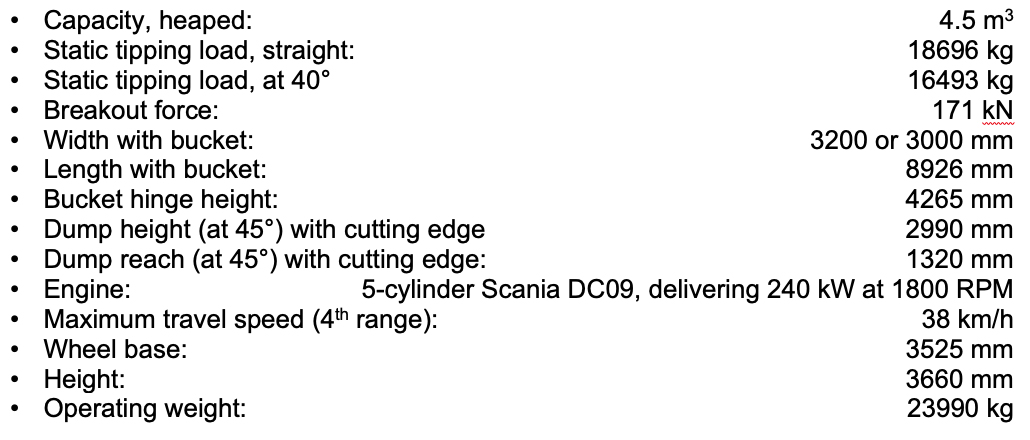

Brief specifications for Doosan DL420CVT-7 wheel loader:

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.