Reduce fuel consumption and increase traction with new differential lock valves – even the tried and tested can be improved, as Bucher Hydraulics demonstrates with its newly enhanced differential lock valves. The advances reflect current market demands for greater energy efficiency, higher wheel power and better vehicle control.

Over the decades, spool-type flow dividers have proven themselves very convincingly in the differential locks of hydraulic traction drives. In recent years, however, the demands of mobile machine operators have risen sharply again. For example, the wish list now includes more intuitive operation, easily controllable driving behavior under difficult conditions, further optimization and automation of work functions, and a reduction in energy consumption. In line with these trends, Bucher Hydraulics has developed new differential lock valves with particularly innovative features.

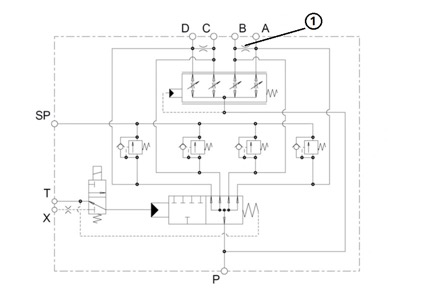

The new DL14 types complement the well-known and proven differential lock valves MT..DV (2 motors), MT..DVD (3 motors) and MT..DVV (4 motors). The DL14s are similarly intended for use in hydrostatic drives with parallel-connected hydraulic motors in either open- or closed-loop mode, and are available for two, three or four motors. Thanks to their design featuring orifices connected in parallel, the DL14 units can also be used for more than four motors. The flow dividers are bi-directional, which means the differential-lock function works in forward or reverse travel. When the differential lock is deactivated, the hydraulic flow distributes itself among the hydraulic motors freely, and with minimal pressure losses. When it is activated, the hydraulic motors are compelled to operate with parallel connections.

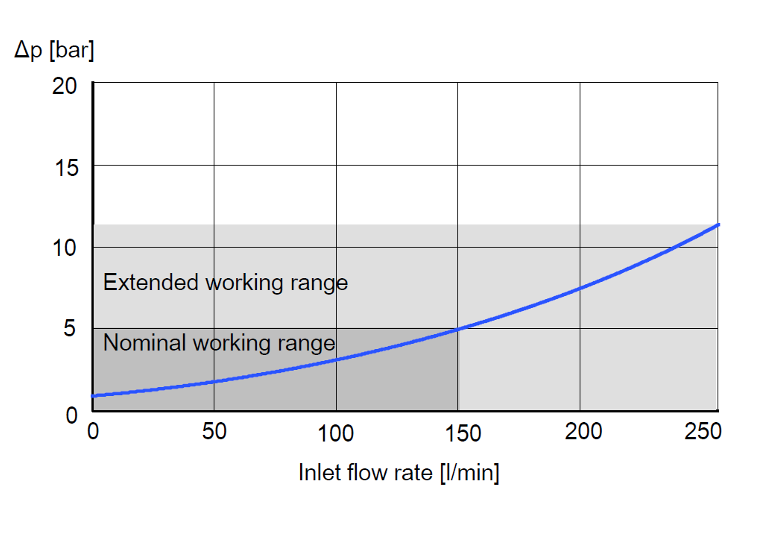

The flow-optimized behavior of the new valve block and the optimized design of the orifice enable a large operating range at high pressures. The DL14 valve blocks with a 2-way differential lock function are therefore very well suited for flow rates up to 250 l/min. The 4-way differential lock is approved for flows of up to 500 l/min.

Another impact of the new design: until now, two sizes have been necessary for a particular operating range: size 08 up to 100 l/min and size 16 up to 250 l/min. The new DL14 covers this range with just one size.

Low pressure losses when switched on

The new valves have also been designed to have exceptionally low pressure losses both when the differential lock is deactivated and when it is activated. More wheel power is thus available. Compared with conventional spool-type flow dividers with a fixed orifice, the energy saving when the lock is activated should not be overlooked. The pressure loss with a 2-way differential lock is then only 5 bar at a nominal flow of 150 l/min and just 11 bar at 250 l/min – and only 3 bar and 5 bar at those same points when the unit is deactivated. In the case of a 4-way differential lock in the activated condition and with an inlet flow of 100 l/min, the pressure loss is around 56 bar less than the current state of the art. This corresponds to a hydraulic power saving of 9.3 kW. Switching from drive mode to differential mode is performed via a 3/2-way switching valve in the low-pressure circuit (maximum 50 bar).

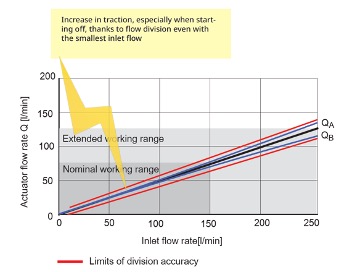

Perfect division even from the smallest flow rates

A locking effect almost from the point that the mobile machine begins to move was at the top of the developers’ specifications. An excellent solution was found using a metering orifice controlled by the incoming flow. Division of the incoming flow begins from flow rates of less than 10 liters/min. In particular, starting off on slippery surfaces is noticeably improved. Personnel can concentrate fully on work functions during difficult driving maneuvers and forward/backward operations.

Pressure compensators for each motor or actuator are integrated in the valve block. Mobile machines in agricultural engineering, forestry and the construction machine sector benefit in particular from the large working range and the fact that the supply to the wheel motors is independent of the load pressure. In line with the trend towards higher operating pressures, Bucher has designed and tested the new differential lock valves for a continuous pressure of 450 bar and a peak pressure of 520 bar. As is the case with the proven MT..DV, MT..DVD and MT..DVV lock valves, integrated make-up valves and anti-shock valves are also available for the DL14. Where fuel savings and better traction are concerned, the features of the new DL14 lock valves will provide particular benefit to a wide range of mobile machines: self-propelled field sprayers, timber harvesters, aerial work platforms from 15 meters, asphalt cold milling machines, road pavers and many more.

In the case of partially electrified machines (hybrid machines) with hydraulic travel drive, greater emphasis will be placed on the energy savings possible with the DL14 shut-off valves. Whether conventional or partially electrified, nothing stands in the way of an update with more wheel power, more traction and greater energy efficiency.

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.