Fuel cell systems have been revolutionising the transportation industry, both in the UK and worldwide. With the recently concluded Project: Trident, the process of applying hydrogen systems has reached the heavy-duty vehicles sector. Project: Trident was a collaboration between Cummins and Aeristech, specialists in designing and developing high-speed electric motors, inverters, and oil-free compressors, suitable for use in Hydrogen Fuel Cell Systems. For this project, Aeristech developed an oil-free electric turbo compressor and brought Cummins closer to becoming the world’s leading provider of decarbonised powertrains for heavy-duty applications.

The main objectives of Project: Trident were to advance the implementation of decarbonised solutions for heavy-duty vehicles, design an e-machine for energy recovery, and create the UK supply chain for the upcoming generation of heavy-duty turbochargers. With the support of Cummins, the team at Aeristech worked towards meeting the demands of the heavy-duty industry, including performance, operational availability, design life, and reliability.

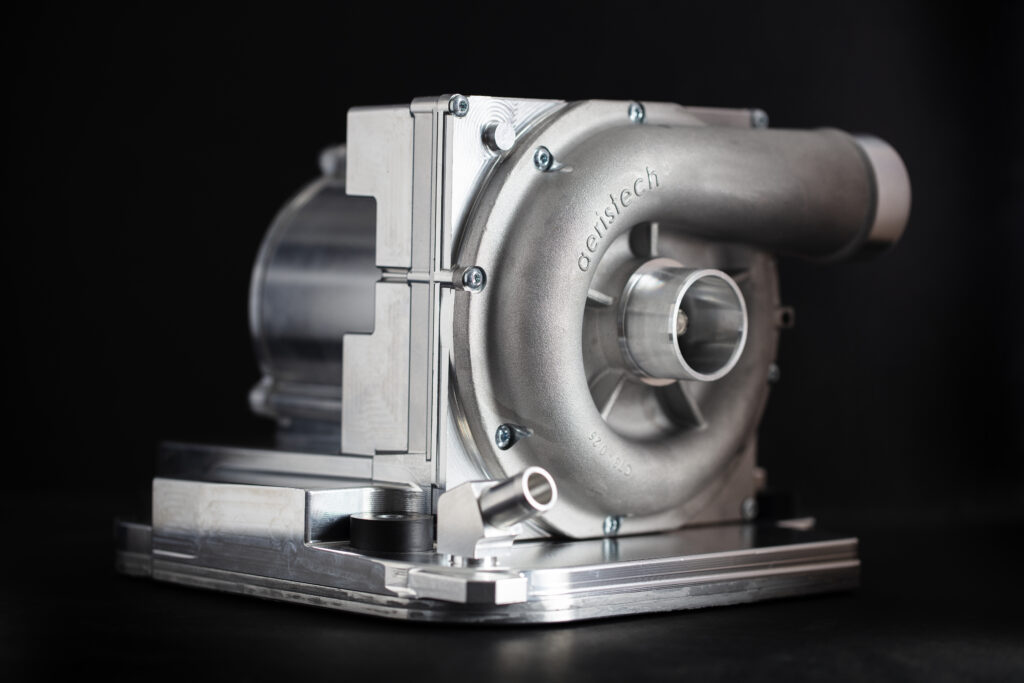

Aeristech succeeded in developing an advanced e-machine platform featuring oil-free bearings coupled with optimised turbomachinery. This involved delivering a high-speed electric motor, advanced power electronics, oil-free bearings, and sophisticated control software. As their main product for this project, Aeristech designed and produced an electric oil-free turbo compressor for an approximate 180kW fuel cell stack integrated with an energy recovering turbine.

The project received the attention of investors, as well as the financial backup of the UK government. Project: Trident was valued at £20 million, with £10 million funded through the Advanced Propulsion Centre, a government-backed initiative in the automotive industry, striving to achieve net-zero emission. The increasing interest in Hydrogen Fuel Cell Systems carries a promise of reducing the carbon footprint of the heavy-duty vehicle industry, as well as the overall environmental impact and creating a greener future with minimal air pollution. Whereas the focus on creating sustainable transportation solutions has initially been put on cars and buses, the time has come for the heavy-duty industry to join this conversation.

“Hydrogen presents a promising pathway for the heavy-duty vehicle industry to achieve sustainability and significantly reduce carbon emissions. By using this clean energy source, we can pave the way for solutions that align with our commitment to the environment. Finalising the Trident programme brought our team enormous satisfaction. We achieved our aim of contributing towards decarbonisation, all while providing our client with highly efficient and innovative technology.”

stated Luke Read, the COO of Aeristech.

Hydrogen proves to be useful when other technologies, such as electric systems may not be enough. Cummins, Aeristech, and their partners created an energy recovery platform designed to enhance CO2 and fuel efficiency across a diverse range of sustainable power solutions. Trident managed to push the boundaries of system efficiency for various thermal propulsion powertrains, including improvements at the vehicle system level, simultaneously enhancing CO2 and fuel efficiency for internal combustion engine-based platforms like hybrids, natural gas vehicles, and lower-emission diesel models. With those advancements, it is fair to say that the next generation of heavy-duty vehicles has now arrived.

Copyright 2017-2023 All rights reserved.

Copyright 2017-2023 All rights reserved.